Oil Field “Christmas Tree” Assembly Lift

Introduction

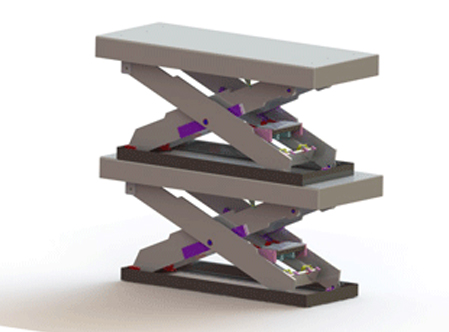

High-capacity, high-travel stacked scissor lift to assemble large oil and gas valve stacks.

Project Challenge

Cameron valve company sought a lifting solution to increase the productivity and safety of its valve stacking/assembly process. At assembly start, the lift would be raised to grade level. As heavy valve stacks were added to the assembly, an operator would incrementally lower the assembly below grade to keep the assembly work at the ergonomic working height of the worker. There were several significant challenges presented in this seemingly simple application. First, the lift had to have a combination of both high travel and high capacity & the fully assembled height of the customer’s valve stack required roughly ten feet of travel while carrying a load close to 20,000 lbs. Second, the new lift had to fit into the customer’s existing pit – which had a small footprint relative to the depth of the pit and lift travel requirement. Third, there could be no permanent structure placed permanently above grade for guidance or support.

Our Solution

After reviewing the application with the customer and equipment distributor, the technical sales team at Autoquip recommended stacking two high-capacity Super Titan lifts on top of each other – to satisfy the customer’s requirements and unique combination of high travel, high capacity, and small footprint. This high-travel lift assembly was given extra lateral stability by installing platform guides on the sides of the pit walls to guide the lift as it was lowered into the pit. The platform was also modified at the customer’s request to include an elevated walking surface around the perimeter of the valve stack. When the lift is lowered below grade, hinged plates are swung in place to serve as the new walking/working surface at grade level. The customer is completely satisfied with this completely below-grade lifting solution, and worker productivity has been increased as a result of keeping their work within the ergonomic “power zone” of the assembly personnel. General Lift Specifications: Lifting Capacity: 19,000 lbs Vertical Travel: 120″ Platform Size: 60″ x 84″ Actuation: Hydraulic

The Results

Through the use of this customized, stacked scissor lift solution, the workstation area has been cost-efficiently updated to include a vital worker productivity improvement with zero impact to the existing pit and floor space required to perform the assembly process.