Industries

Aerospace

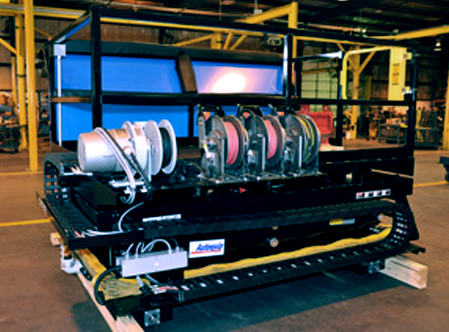

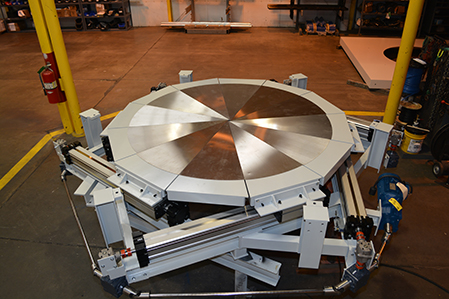

Autoquip is proud of its history providing specialized lifting equipment to the Aerospace industry. We have partnered with the top aerospace manufactures to design lifting solutions for manufacturing of aircraft, repair, maintenance and assembly. Autoquip has the technical expertise and manufacturing capability to help you develop an effective and reliable custom equipment solution.

Experience & Expertise

Typical lifting & handling solutions Autoquip has designed & manufactured for the Aerospace Industry include:

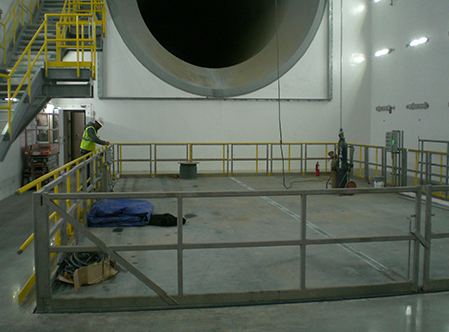

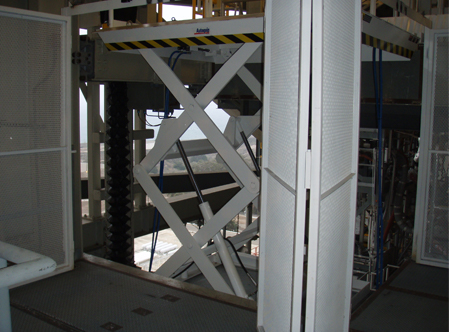

High travel scissor lift and heavy-duty ram lift configurations raise large wheeled carts carrying jet engines to the fixtures near the top of the test cell.

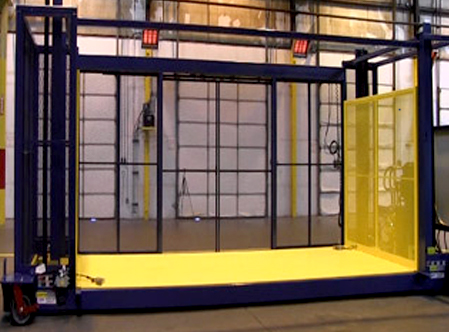

Fixed and portable scissor lifts, with and without adjustable shuttle decks, provide assembly personnel variable vertical and lateral access to all surfaces of a wing and its tool during assembly and inspection.

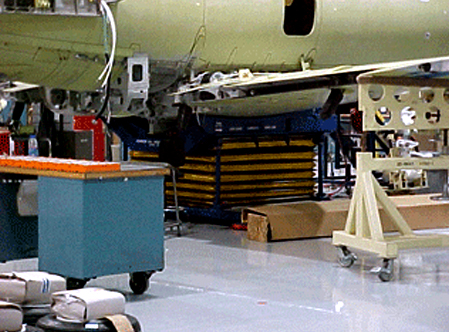

Multiple portable hydraulic scissor lifts working in tandem to provide variable working heights of the entire jet fuselage.

Portable, adjustable scissor tables move and position satellites between storage and launch facilities.

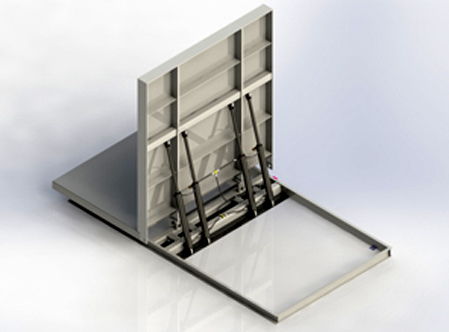

Lightweight fixed and portable scissor lifts reduce overall weight for ease of manual positioning by personnel. This reduction in weight is also critical on the cantilevered work platforms used to access fuselage sections during assembly.

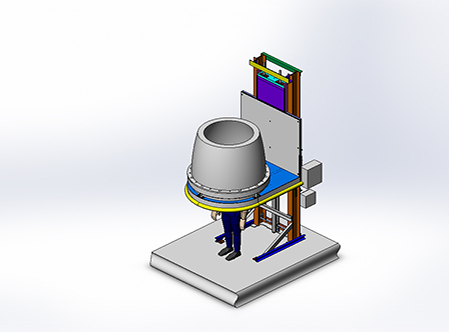

Stacked scissor lifts or single ram platform lifts are used to ergonomically position a jet engine standing on end, lowering it into a recessed pit while workers stand on and work from the adjacent, fixed floor level.

Autoquip Clients

We have worked with some amazing teams.