Applications

Coil Handling

Autoquip has designed custom solutions for product loading and unloading, upending and downending, and the transporting and/or lifting of rolls and coils for a wide variety of industries and applications. Equipment designs all include features uniquely suited for coil-handling applications.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for coil handling applications include:

A fixed height car with V-deck top and powered traversing base is used to transport rolls on a fixed track from one work cell to another, then transports empty "cores" when returning.

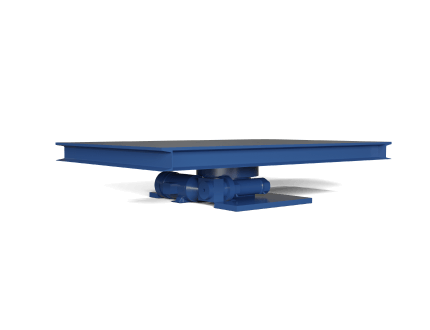

A custom designed scissor lift with traversing base and tilting top with V-deck is used to remove rolls from a mandrel, transport them, raise the roll, then "kick" (tilt) the roll off the side of the lift onto the in-feed side of a slitting machine.

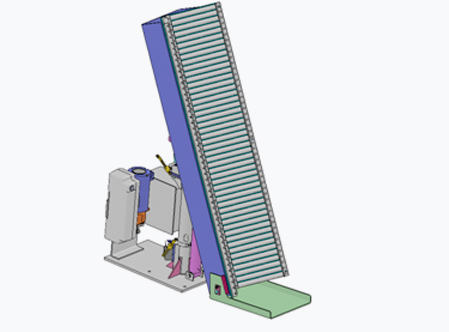

This special 90-degree tilter is used to receive rolls of varying lengths on one platform wing, and manually shuttles the roll until its end is in contact with the second tilter wing prior to upending the roll on end.

A custom scissor lift with powered transport base and V-deck is used to pick rolls out of "saddles," transport them down a fixed track, and then place them back onto a waiting "saddle" for staging.

A special 90-degree tilter is used to receive coils from an overhead crane, then upend them from their sides to an upright position on pallets.

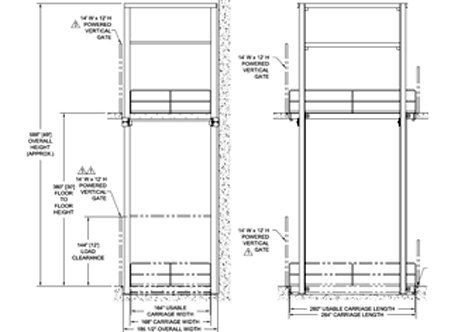

A custom vertical reciprocating conveyors lift, using rack and pinion equalization as well as four direct-acting cylinders, is used to raise a large platform with six large rolls of paper between floors in a paper manufacturing facility.