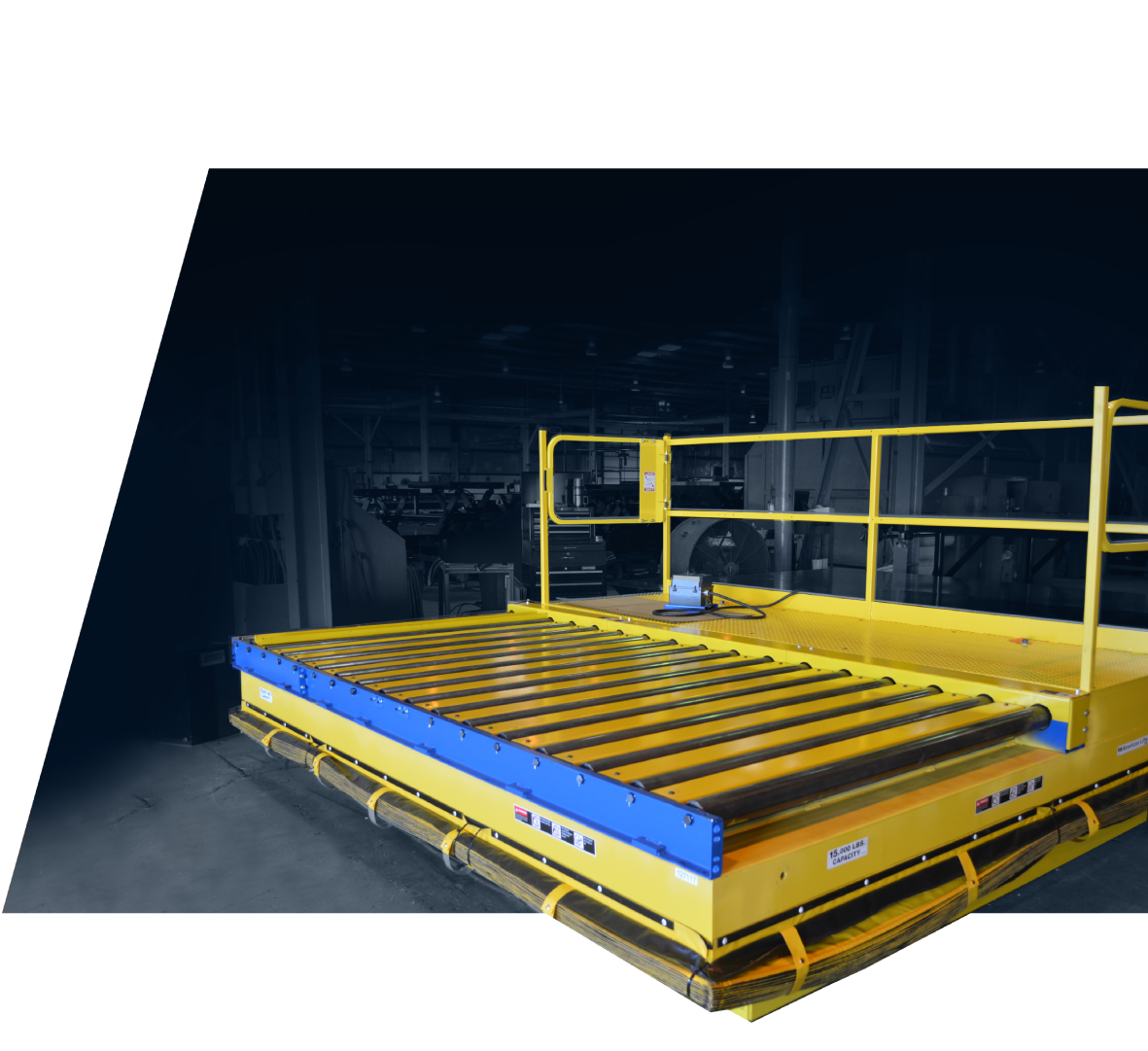

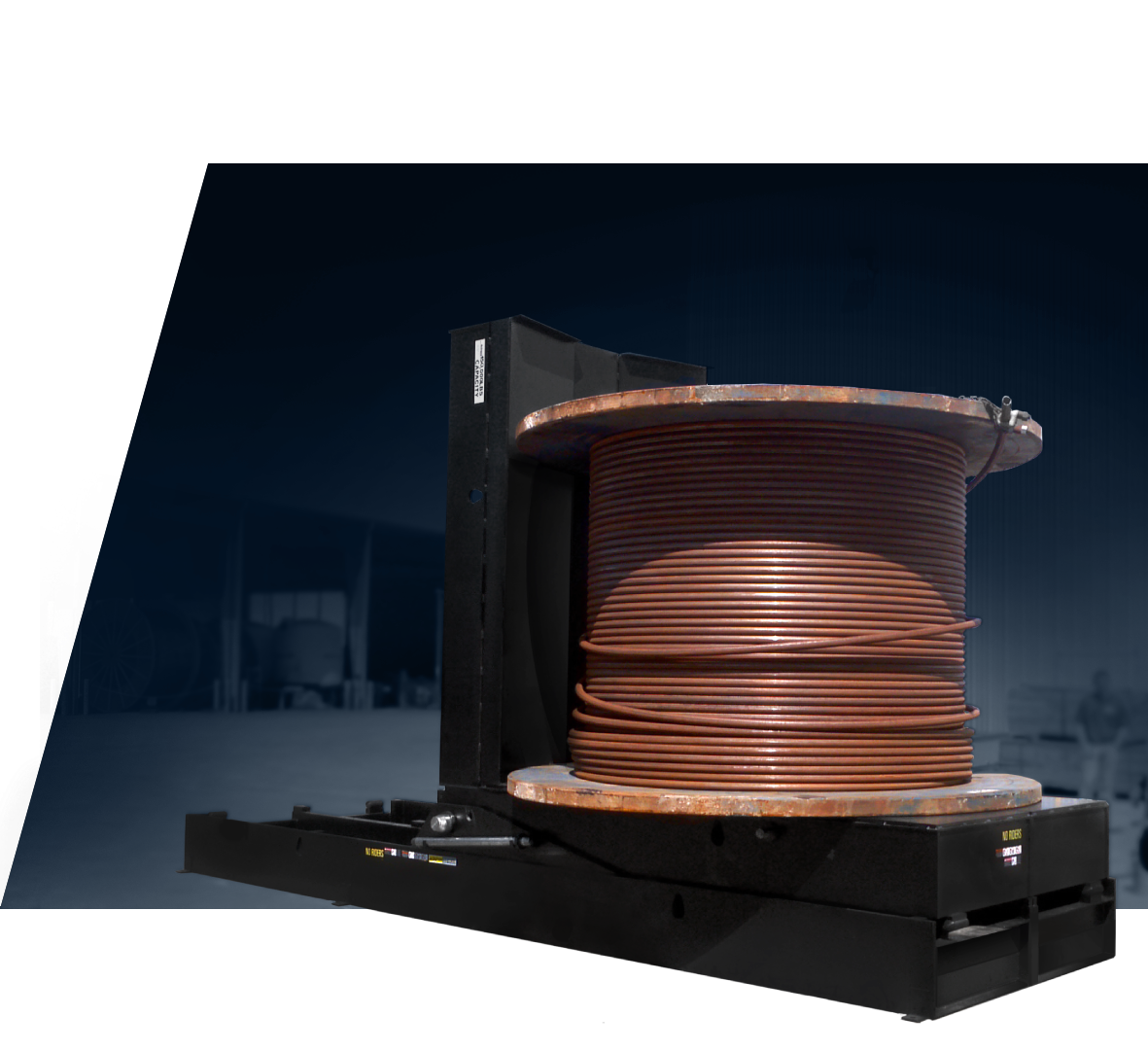

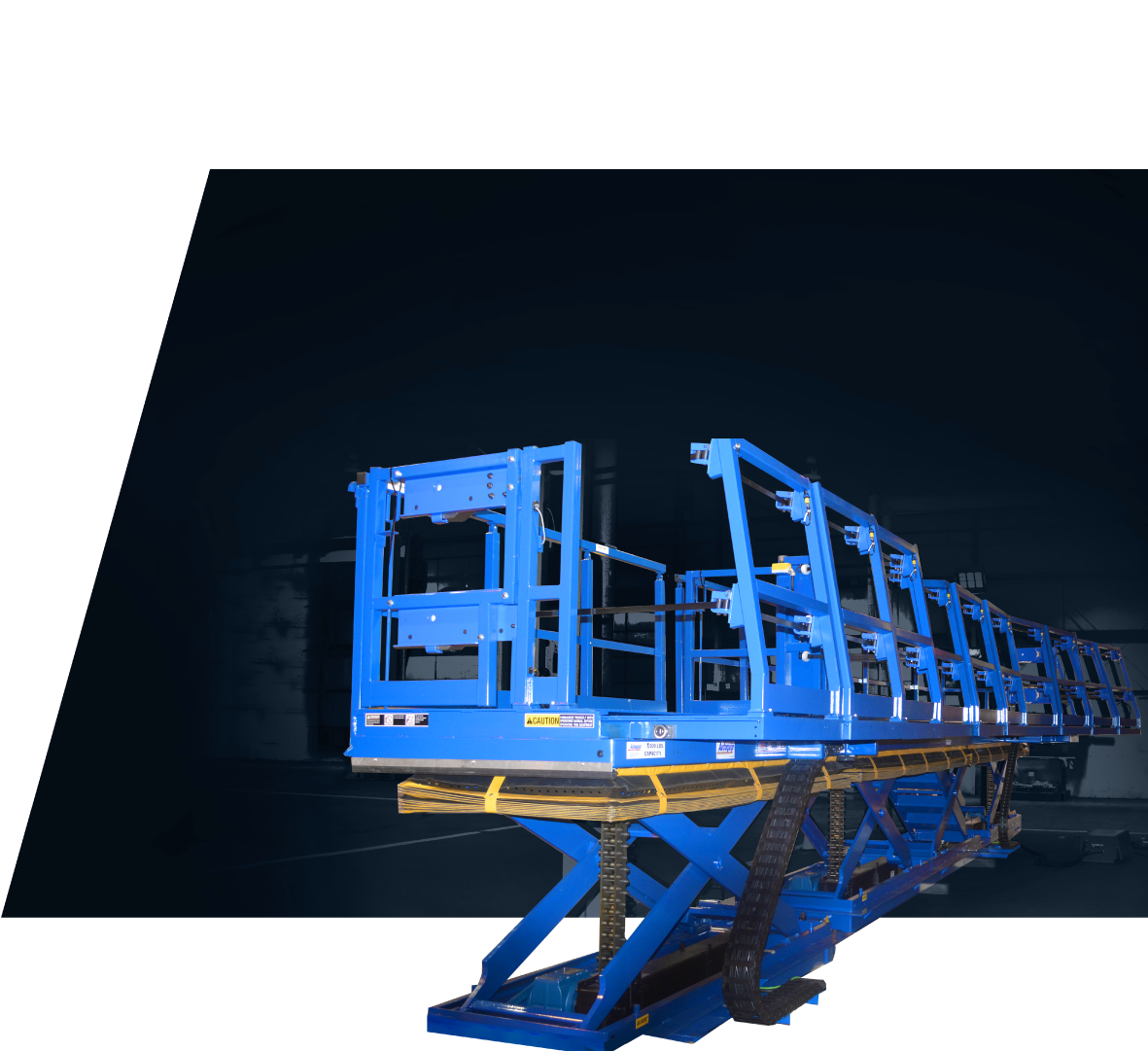

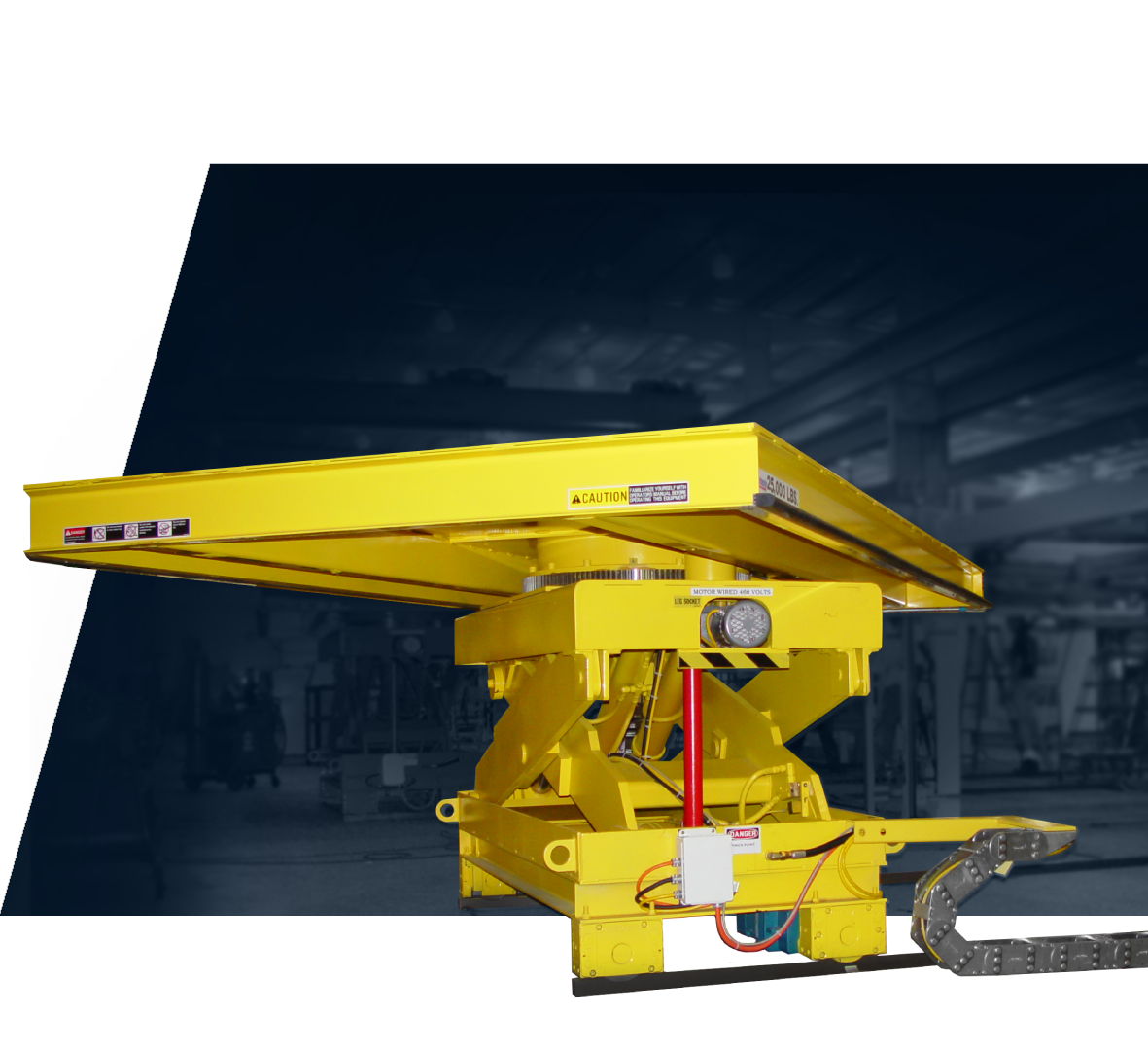

Custom-Designed Lifting Solutions

When your application demands more than the standard, our custom design solutions are made to solve your unique manufacturing challenges.

Watch VideoSolving Complex Challenges Is What We Do

At Autoquip, we focus on developing and implementing the latest design, technology, and production techniques into every lift we build. Our highly skilled team of engineers and technical experts have maintained a reputation for taking on diverse specialized projects and delivering exceptional results.

Whether you need your lifts to be mobile, high-cycle, automated, or particularly sized and configured, Autoquip has the most customizable capabilities to craft the right lift for you.

See how we've solved several unique challenges in these case studies.

Superior Control Capabilities

Autoquip’s in-house controls division has developed a wide variety of advanced solutions to make your lift smarter. AQ Connect™ is an adaptive and intuitive controls system that uses self-diagnostic maintenance monitoring technology. It is available across all product lines to give you flexible functionality and oversight, ensuring top safety precautions and an increase in productivity on the manufacturing floor.

View AQ Connect

Contact a Lift Expert Today

Whether your lift requires an advanced smart panel like the AQ Connect or standard controls for a simple operation, Autoquip's in-house Controls Division is fully capable of installing the best system to suit your needs.

Contact Us