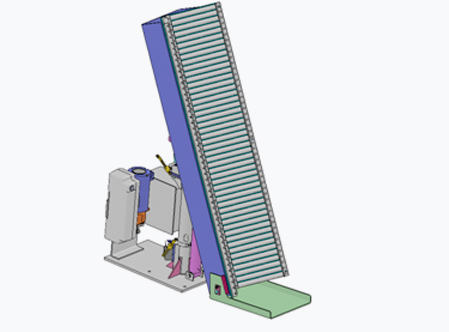

High Hinge Tilter with Multi-Positioning Cradle

Introduction

High-hinge tilter lifts and reorients heavy rolls of film into mandrels for processing.

Project Challenge

3M Corporation was experiencing excessive damage to their 100-200 pound rolls of sensitive and easily-damaged film product as it was being raised, repositioned, and loaded into mandrels manually by employees. 3M also recognized the potential for back injury and accidents due to the poor ergonomics involved in this manual material-handling task. 3M challenged Autoquip with making their film processing more efficient and safer by requiring a specialized design that was capable of the following: 1. Must be able to handle rolls of variable diameters 2. Rolls must be protected from damage during handling 3. Must be able to receive rolls oriented vertically and reposition them into a horizontal orientation – with limited floor space 4. Rolls must be able to be delivered/transferred onto the equipment via wheeled carts (low profile – “zero” lowered height) 5. Must be able to perform entire process with one (1) employee 6. Solution must be simple, cost-effective

Our Solution

Because of the low profile requirement and need to rotate the product within a very small footprint, a special vertical post lift with high hinge tilter was ultimately recommended and selected. The lift and tilt functions are actuated by separate double-acting hydraulic cylinders to minimize the equipment footprint and effectively position rolls of variable diameters. The unit was equipped with a hinged floor-level ramp for loading with a wheeled cart, and equipped with a “V”-shaped cradle deck and specially coated conveyor rollers to convey multiple diameter rolls of film with minimal employee interface and minimal potential for damage.

Autoquip tested and delivered a low capacity, low profile, special high-hinge tilter actuated by a vertical hydraulic cylinder in a double-acting hydraulic circuit. This solution provided the least intrusive, most stable, highly flexible, and most cost-effective positioning solution for the application. The customer is completely satisfied with this vertical post lift and tilt combination unit. Worker productivity has been measurably higher as a result of minimizing human interface with the equipment, and scrapped product due to damage during handling has been virtually eliminated. Lift

Specifications for this Unique Application:

Lifting & Tilting Capacity: 200 lbs.

Platform Size: 18″ x 60″ with floor-level ramp & V-deck cradle & special coated rollers

Vertical Travel: 9.44″

Power Source: Standard wall outlet (115VAC/1phase)

Control signal: Hand held push button

Actuation: Double-acting hydraulic cylinders

The Results

Autoquip was able to evaluate the customer’s process and visually comprehend the customer’s needs. We were able to provide an economical means to handling their valuable material, thus eliminating damage to the product.