Small Jet Wing Mating Lift

Introduction

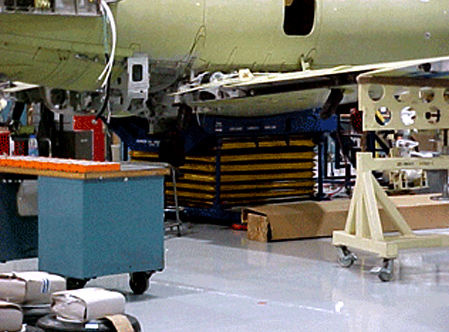

High Capacity Scissor Lift used to attach a one-piece wing system to the underside of aircraft fuselage.

Project Challenge

A manufacturer of small jets was researching various means to improve the process of attaching the wing to the fuselage of a business jet. The current method of using adjustable jack stands to perform this task takes too long and requires the assistance of too many people. This customer specified a lifting “tool” which would overcome all the challenges of this application: 1) weight of fuselage and wing must be supported by one lift, 2) lift must be able to transport the wing, or wing plus fuselage, from one station to another, 3) lift must be able to operate at two different speeds – either fast (while the wing is being raised between lowest and highest elevations) or slow (while the wing is being positioned for attachment).

Our Solution

Autoquip’s design team met with the industrial, safety, and tooling engineers from the customer’s factory to review potential lifting solutions. A high-capacity scissor table was selected from our Supertitan family of hydraulic lifts, and customized with a hydraulic circuit that either sent full pump flow to the lifting cylinders for the faster speed, or partial flow to the cylinders for the slower speed. The scissor lift had a 42-inch wide base for added load stability, and was equipped with a specialized base frame that could be fitted with the customer’s specified brand of air bearings – for ease of transporting the loaded lift.

The lift was also equipped with a free-fall arrest device that would completely stop the descent of the lifts in the event of a catastrophic hydraulic hose failure. The tooling engineer is completely satisfied with this extremely robust lift solution, as well as the many customer features that were added to enhance safety and productivity. The assembly personnel are able to complete the wing-mating process in less overall time with fewer specialized jack stands – saving valuable floor space.

Lift Specifications for this Unique Application:

Model: 48LL15

System Capacity: 15,000 lbs.

Vertical Travel: 48″

Fast Speed: 2 inches per second

Slow Speed: 0.25 inches per second

Actuation: Hydraulic

The Results

Through the use of this customized hydraulic lift, the customer has experienced a tremendous improvement in efficiency for this critical part of the assembly process. Overall time to complete a wing-mate was reduced from hours to minutes.