Material Handling Lifts for Clean Room Environments

Modern clean rooms have grown exponentially since their creation in the 1960s. These specially designed environments control the levels of pollutants such as dust, airborne microbes, aerosol particles, and chemical vapors. Clean rooms play an essential role in industries where the slightest contamination can jeopardize an entire product order. In this post, we explore their use in the food and pharmaceutical industry and learn how Autoquip helps businesses maintain safe and compliant production environments.

Biotech & Pharmaceuticals

Clean rooms are pivotal in the biotech and pharmaceutical sectors because of the critical importance of product purity, safety, and consistency. Products such as injectables, eye drops, and vaccines must be free from microbial contamination; this can only be achieved in a clean environment. Drug manufacturers and compounding pharmacies also require sterile room conditions to ensure patient safety and product integrity.

The U.S. Food and Drug Administration (FDA) has regulations for producing sterile drugs. This includes guidelines on clean rooms and associated environments, as outlined in their Current Good Manufacturing Practices (CGMPs). Additional clean room and controlled environment standards from USP (The United States Pharmacopeia) and ISO 14644 must also be complied with.

Food & Beverage

While clean rooms in the food and beverage manufacturing vertical are not as widespread as in biotech and pharma, their use is growing consistently. Consumer demand for safe, pure, high-quality foods is increasing, and clean rooms help manufacturers control contamination. They have become essential for manufacturing certain food types, including baby food, infant formula, dairy items, and dietary supplements.

Though convenient, the soaring popularity of ready-to-eat (RTE) products (including breakfast cereals, pre-packaged meals and salads, and pre-cooked meats) comes with concerns regarding processing and packaging and the contamination risks associated with mass production.

The FDA has established several regulations applicable to food and beverage manufacturers. Although they don’t mandate clean rooms, they impose strict standards and guidelines for controlled environments, sanitary operations, and safe handling.

Supporting Compliance & Safety

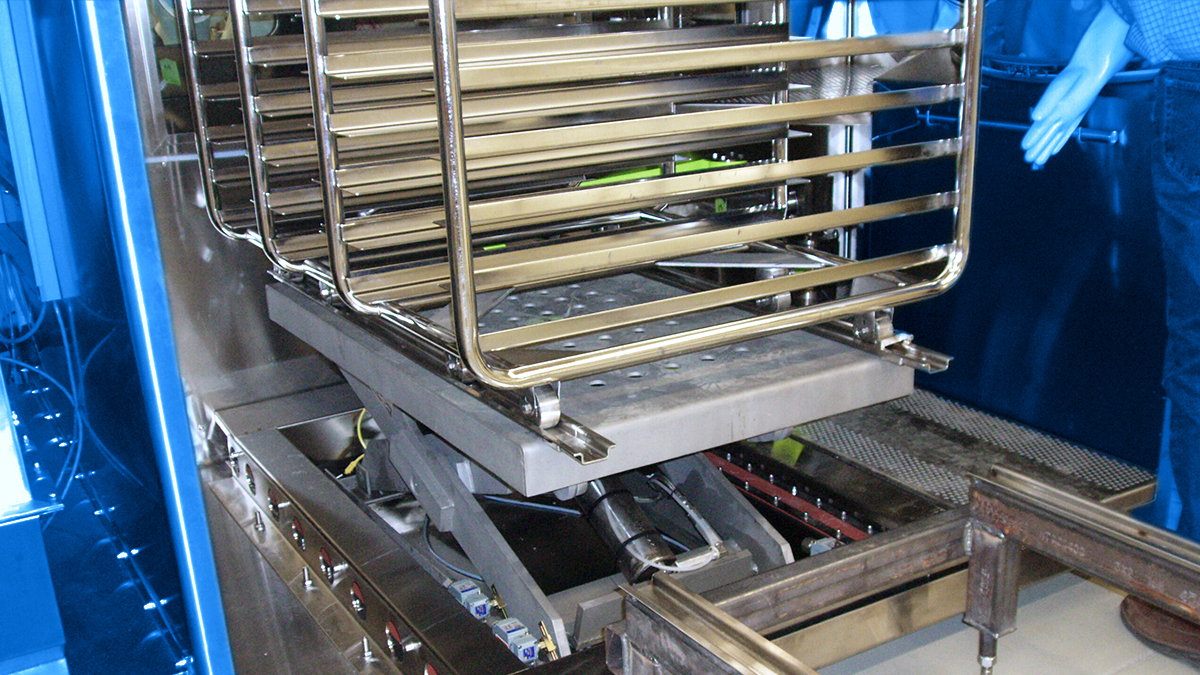

When performing material handling activities in clean rooms, the equipment must be easily sanitized, non-particle shedding, ergonomic, and corrosion-resistant. Autoquip lifts help you optimize your operation using the following:

- Sterile Steel: Autoquip has extensive experience designing custom stainless steel lifting equipment suitable for clean room applications. We offer a variety of equipment options, including our versatile line of scissor lift tables, which can be customized to meet your specific conditions and requirements. And we work with you to ensure your new equipment complies with industry regulations and guidelines.

- Injury-Reducing Designs: These workplaces can be challenging for employees due to the stringent protocols. Autoquip lifts can help your team minimize fatigue and physical strain while increasing productivity, accuracy, and efficiency without compromising safety.

- Fluid-Free Options: When you need to manufacture products without the risk of hydraulic leaks or spills, our ABS Pneumatic Lifts get the job done. Airbag actuators drive these reliable scissor lifts, making them ideal for clean room settings.

- Water-Friendly Surfaces: Does your application require frequent wash down? As our case studies in the food and veterinary sectors demonstrate, the Autoquip design team can deliver solutions that protect circuitry, hydraulics, and other essential components from exposure to water. And in addition to our high-grade stainless steel, we offer various materials, surfaces, coatings, and safety features to further customize or upgrade your unique, clean room operation.

Autoquip: Where Tradition Meets Innovation

When it comes to blending tradition with innovation, few do it as seamlessly as Autoquip. Our lifts are designed with precision, crafted with expertise, and implemented with care. They stand as a testament to our commitment to quality, excellence, and customer service. With 75 years of experience under our belt, we invite you to discover the Autoquip difference. Reach out to us for a free quote today; we’re ready to get started on your next project!