Customizing Lift Tables: Options and Configurations

When it comes to material handling, there’s no one-size-fits-all solution. Autoquip’s scissor lift tables offer unmatched versatility, but what truly sets them apart is their extensive range of customization options. From tailored dimensions and weight capacities to specialized features like turntables, mobility enhancements, and advanced controls, our lifting devices can be engineered to meet your unique application requirements. With Autoquip’s expertise in industrial customization, the sky is truly the limit for lifting solutions that fit your operations.

Explore how Autoquip’s custom lift tables can improve your workflow. Reach out to our team for a design consultation today.

Why Custom Lift Tables Are the Ultimate Access Solution

Autoquip’s scissor lift tables are the most reliable and versatile lifting solutions on the market. Their adaptability makes them ideal for a variety of industries, including manufacturing, warehousing, automotive, and aerospace. However, it’s the ability to customize these lift tables that truly unlocks their potential. With options for platform size, table capacity, mobility, materials, and safety features, our custom lift tables ensure precise performance for your unique operational demands. From light and medium duty tasks to managing extreme loads, we have the scissor lift solution for your business.

Engineered for Your Industry and Application

Whether you need a compact lift for tight spaces, a heavy-duty solution for industrial applications, an electric powered hydraulic lift, or a high-speed table for automated workflows, Autoquip’s team of designers and engineers collaborates with you to create lift table configurations that maximize efficiency, safety, and productivity.

Our process begins with understanding your specific challenges and operational goals, ensuring every lift table is tailored to meet your exact requirements. From concept to final implementation, we leverage decades of expertise and advanced techniques to deliver solutions that not only perform seamlessly but also enhance your overall workflow. Autoquip’s commitment to customization means no application is too complex—if you can envision it, we can build it!

Custom Lift Table Configurations: Tailored for Precision and Operability

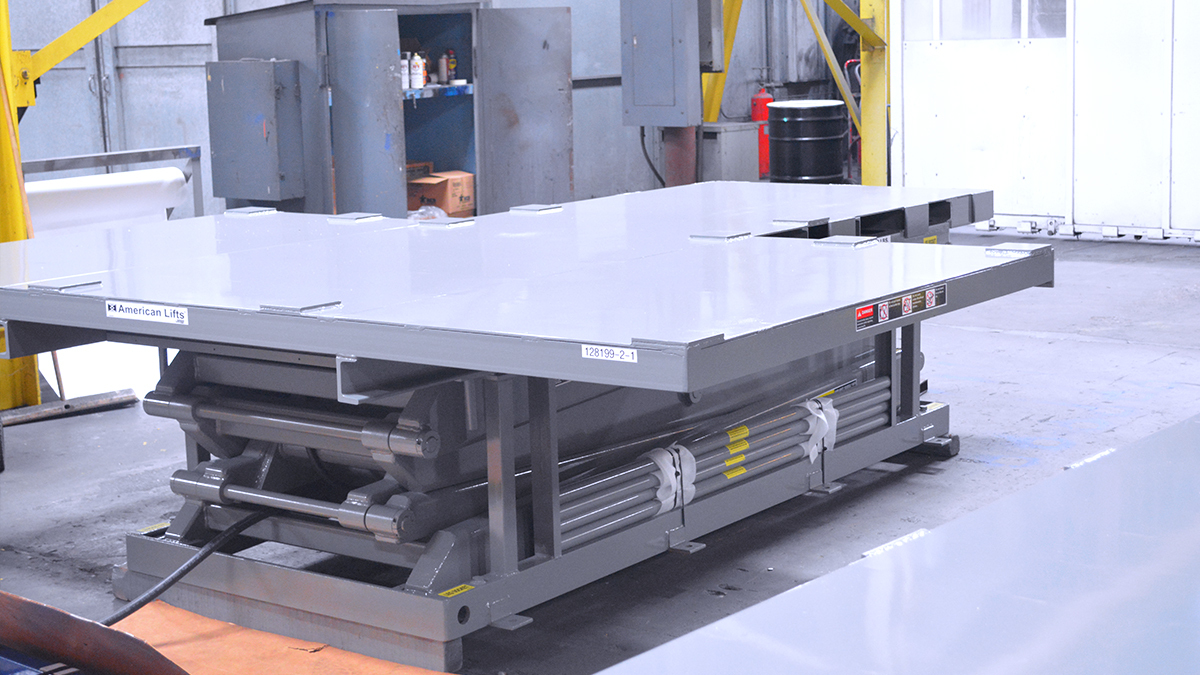

Platform Sizes and Configurations

Autoquip offers a range of platform sizes to meet your unique operational needs. From compact platforms for tight assembly lines to oversized surfaces for handling large materials, our platform size options ensure seamless integration into your workflow. Whether you need to lift personnel, equipment, or bulky goods, we tailor the platform dimensions to match your specific application.

Our scissor lift tables can be configured with additional features to enhance functionality. Options like rotating platforms, folding edges, shuttle decks, and conveyors allow you to perform tasks with precision and efficiency. Turn-and-rotate platforms, for example, enable operators to access materials from multiple angles, improving productivity in assembly and manufacturing environments.

Customizable platform features include:

- Multi-position platforms with folding edges or extensions for adaptability

- Rotating platforms for enhanced access and efficiency

- Shuttle decks for extended reach and dynamic workflows

- Integrated conveyors to support seamless material transfer

- Solutions tailored for pallet handling to streamline warehouse and loading dock operations

High-Capacity Lifting Solutions

For applications requiring heavy-duty performance, Autoquip offers high-capacity scissor lift tables capable of lifting extreme loads with precision. Whether moving oversized equipment or managing bulk materials, our lifts are designed to handle heavyweight applications with superior stability.

Our high-capacity features include:

- Lifting capabilities of over 100,000 pounds

- Reinforced steel structural components for enhanced durability

- Heavy-duty hydraulic systems for smooth, consistent operation

- Minimized platform deflection to maintain stability and safety under heavy loads

For unparalleled capabilities to manage massive equipment and material loads, look no further than our flagship Super Titan series. Custom lift options allow you to scale its performance to meet the most demanding industrial challenges. With weight ranges from 18,000 to 135,000 pounds and a variety of platform dimensions and heights to choose from, there’s an option for every heavy-duty application.

High-Travel Lifting Options

When vertical movement is critical, Autoquip’s high-travel scissor lift tables deliver unmatched reach and performance. These lifts are designed for applications that require extended lift heights, such as multi-level facilities, mezzanine access, and specialized assembly operations.

High-travel scissor lifts provide:

- Vertical lifting ranges for multiple-story access

- Stabilized performance to ensure safety at extreme heights

- Custom platform designs to maintain balance and precision

Whether you need to lift personnel, equipment, or materials across significant vertical distances, our high-travel solutions can be customized to meet your exact requirements.

Mobility Enhancements for Flexibility

Need a lift table that moves? Autoquip’s custom mobility options provide the flexibility your operations demand. Whether you require manual or powered mobility, our designs ensure smooth and efficient transport across your facility.

Mobility options include:

- Caster wheels for easy repositioning

- Track-mounted systems for precise linear movement

- Air bearings for frictionless maneuverability in cleanrooms

- Fork pockets for forklift transport

These enhancements allow you to integrate scissor lift tables into dynamic workflows, improving accessibility and efficiency.

Features That Enhance Custom Lift Table Performance

Safeguard Your Operations with Advanced Safety Features

Autoquip prioritizes safety in every custom lift table design. With a variety of safety features, we ensure safe operation and operator protection in any environment.

Safety options include:

- Proximity sensors to detect obstructions and prevent accidents

- Safety rails and toe guards for personnel safety

- Emergency stop controls for immediate power shutdown

- Load locking mechanisms to stabilize heavy materials

Precision Controls for Seamless Operation

Advanced control features allow you to operate your lift tables with precision and ease. Autoquip provides control solutions that enhance performance, whether for manual operation or integrated automation systems.

Control options include:

- Programmable logic controllers (PLC) for automated workflows

- Wireless remote controls for flexible operation

- Push-button pendant stations for easy access

- Variable speed controls for smooth and consistent lifting

Elevate Efficiency with High-Tech Automation

Automation can take your lift table capabilities to the next level. Autoquip’s custom lift tables can be seamlessly integrated into automated workflows to streamline operations and maximize efficiency.

Automation features include:

- Programmable lifting cycles for consistent, repeatable tasks

- Integration with conveyor systems for material flow optimization

- Sensors and feedback systems for precise positioning

- Custom controls to match your existing automation infrastructure

Built to Last: Durable Materials and Finishes

Autoquip’s custom lift tables can be built with specialized materials and finishes to meet industry-specific requirements. From heavy-duty steel for durability to stainless steel for cleanroom environments, we offer a variety of materials to suit your application.

Options include:

- Non-slip surfaces for improved operator and material safety

- Corrosion-resistant coatings for harsh environments

- Stainless steel finishes for food-grade, wash-down, and cleanroom applications

- High-wear finishes for extended durability

Our material customization options ensure your lift table can withstand the demands of your environment while maintaining optimal performance.

Ready to Design the Perfect Lift Table for Your Needs?

With Autoquip’s custom lift tables, you get more than just a lift—you get a solution tailored to your operations. Autoquip has been working with customers for over 75 years to design and configure scissor lift tables that streamline operations and protect their workforce.

From platform dimensions to advanced mobility and safety features, we can customize every aspect of your lift table to deliver the performance you need. Let Autoquip help you find the perfect lifting solution for your business.

Are you ready to explore your custom lift table options? Contact Autoquip today for a free quote.

Autoquip: Your Partner for Custom Lift Table Solutions

Custom lift tables from Autoquip offer endless possibilities for enhancing your operations. With options for size, capacity, materials, and advanced features, our solutions are designed to address your unique challenges. Whether you’re looking to improve efficiency, increase safety, or streamline workflows, our team of experts is here to deliver.

By choosing Autoquip, you’re not just investing in high-quality equipment—you’re partnering with the industrial lifting industry leader. From concept to completion, we work with you to develop the ideal solution for your application.

Make 2025 the year you transform your operation. Contact Autoquip today; we’re ready to get started on your project!