Hydraulic 4 Post VRC Transfers Large Paper Rolls

Introduction

4-post hydraulic VRC lift to transfer multiple rolls of paper between two fixed landings.

Project Challenge

A method of moving up to six (6) rolls of paper between the production floor and the storage level above, each roll weighing approximately 5,500 pounds. Also, on occasion, they wanted to move a fork truck between levels, with or without rolls of paper. The current method of moving fork trucks or rolls of paper between levels was to drive outside and around the building on the sloped parking lot. GP needed a design solution that was: 1) extremely robust – as it would experience a lot of traffic and heavy loads, 2) extremely large to accommodate the total number of rolls of paper they wanted to move at one time, and 3) essentially free-standing, as the lift structure would be placed in the factory adjacent to a raised mezzanine, but not structurally tied to the mezzanine.

Our Solution

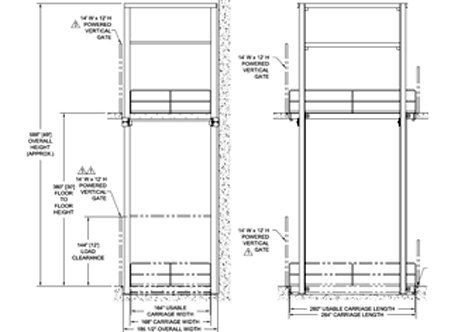

Autoquip met with its equipment distributor and representatives from Georgia Pacific to review performance specifications and drawings of the factory floor plan. A special high capacity, hydraulic 4-post vertical reciprocating conveyor (VRC) was ultimately recommended because of its ability to convey large, heavy loads over high vertical travels, and its virtually self-supporting lift structure. This unique lift would be raised and lowered by four large, direct-acting cylinders one at each corner of the lift. The four cylinders were synchronized in motion by a hydro-mechanical system that consisted of high-efficiency flow dividers/combiners at the 40HP pump unit, and a rack and pinion system mounted beneath the main carriage which helped to time the four corners especially in the event that the carriage experienced an off-center load.

Pneumatically-powered deck locks were mounted to the guide beams adjacent to the elevated mezzanine and would swing out on demand to help support the carriage as heavy fork trucks enter and exit the lift while in the raised position. Safety features included a carriage free-fall arrest system, interlocked access doors, and personnel guarding in compliance ANSI B20.1.

Lift Specifications for this heavy-duty application:

Lifting Capacity: 35,000 lbs. live load

Axle Load Capacity: 26,000 lbs.

Vertical Travel: 360″

Platform Size: 68″ x 264″

Lifting Speed: 17 FPM

Hydraulic Power Unit: 50HP/460VAC

Actuation: Hydraulic – with Hydro-mechanical synchronization

The Results

The completely custom-designed, high-capacity, high-impact lift has improved efficiency in transferring rolls of paper and increased overall throughput of the factory.