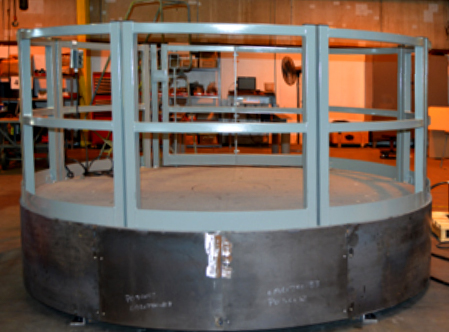

Circular Lift Platform Built In Sections for Onsite Assembly

Introduction

Some assembly required. Autoquip builds a custom circular lift platform to be assembled onsite for a highly sensitive application at a national weapons laboratory.

Project Challenge

Sandia National Laboratories are a government contractor for the U.S. Department of Energy’s National Nuclear Security Administration (NNSA). They manage the nation’s nuclear weapons stockpile; provide research, development, and testing services; and manufacture specialized non-nuclear products and components for national defense and security applications. At their labs in New Mexico, they were looking for a solution to access underneath the nuclear centrifuge to conduct maintenance. The dynamics and sensitivity of their product provided an interesting material handling challenge for Autoquip.

Application Requirements:

- The lift needed to travel up to 64” to reach the bottom of the centrifuge.

- The lift platform shape is specified to be 102” in diameter to match the round contour of the lab room, and also have an 18” hole cut out of the center, so that the bottom of the platform would not push up against the bottom of the centrifuge.

- For the lift to be installed in the confines of the lab room, the lift had to fit through a 30”x30” opening which meant the lift platform and leg sets had to come disassembled to be put through the opening. Once inside, the lifts assembly would need to be reconnected to the lift base with a fastening option other than welding.

Our Solution

To meet all application requirements, Autoquip custom built 2 extra narrow scissor lifts from our Tork product family, the T2. Each T2 is designed with extra narrow leg sets and will be positioned on opposite sides of the circular platform to avoid interference with the cut out hole in the center. The leg sets and platform were manufactured with bolt slots and shipped disassembled, so that the lift could be transferred to the lab room and fit with in the narrow room opening. The whole lift can be bolted together since welding is not allowed.

Autoquip designed the lift with secure lifting devices to keep the workers safe especially in this super sensitive work environment. Safety features include SlipNot tread surface to provide a safe working surface, 48″ wide flat spot with gate for loading and unloading parts, handrails, and special steel skirts with pressure sensing edge to detect part interference and remain ANSI MH29.1 compliant.

Lift Specifications:

Product Family: Tork

Model #: T2-72-040

Capacity: 3,000 lbs.

Platform: 102” diameter

Travel: 64”

Actuation: Hydraulic

AQ Project Ref. # 119618 9SPI-24070

The Results

Our dealer, Medley Material Handling contacted Autoquip about this project because they know we offer the highest quality of custom design solutions. The custom T2 lift design provided a solution to handle this delicate maintenance work and provided the workers a safer process within their sensitive environment.