Lift, Tilt & Turn for Painting Parts for Oil & Gas Industry

Introduction

Lift, tilter and turntable allow for parts to be positioned at different rotations in order to apply the correct paint coverage.

Project Challenge

Lord Corporation manufacturer of industrial parts for the oil & gas industry was looking for a multi-functional lift equipment for improving their paint finishing process.

The customer’s goals for the new equipment included:

- Explosion proof to install inside their paint booth.

- Adjustable to accommodate different size parts and improve overall coating.

Our Solution

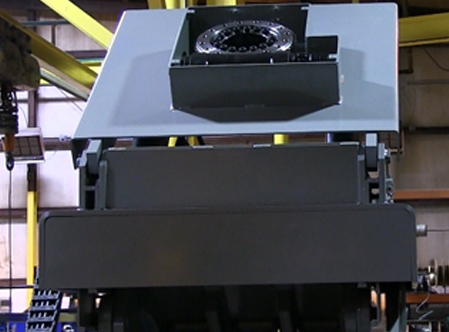

Autoquip designed a heavy duty Super Titan scissor lift with a tilter and turntable mounted to the platform. The tilter and turntable allow the parts to be positioned at different angles and rotations in order to apply the correct paint coverage. The turntable is removable and can be interchangeable to 3 different size turntables to fit the varying part sizes that will go through the paint booth. The lift is powered by an air motor to meet the explosion proof requirements, and the turntable is adjustable with variable speed controls for controlling the paint thickness.

Specifications:

Model: 24L31, FF9060 with Tilt & Turn

Capacities: 6,000 lbs.

Platform: Interchangeable turntables

Travel: Vertical – 24”, Tilting 90°, Rotational 360°

Power Unit: Remote Air Motor Power Unit

The Results

- Autoquip was able to successfully provide a lift equipment that will dramatically improve their paint finishing process.

- The lift operates with air powered motor for explosion proof compliances.

- Multi-functional with lift, tilt and turn to accurately apply the right amount of coating.