3 Types of Actuation – How to Choose Between Mechanical, Pneumatic, and Hydraulic Lift Tables

The three most common types of actuation to operate industrial lift tables are hydraulic, mechanical, and pneumatic. By understanding the types available and their use, you can make an informed decision on what type is right for your application and environment.

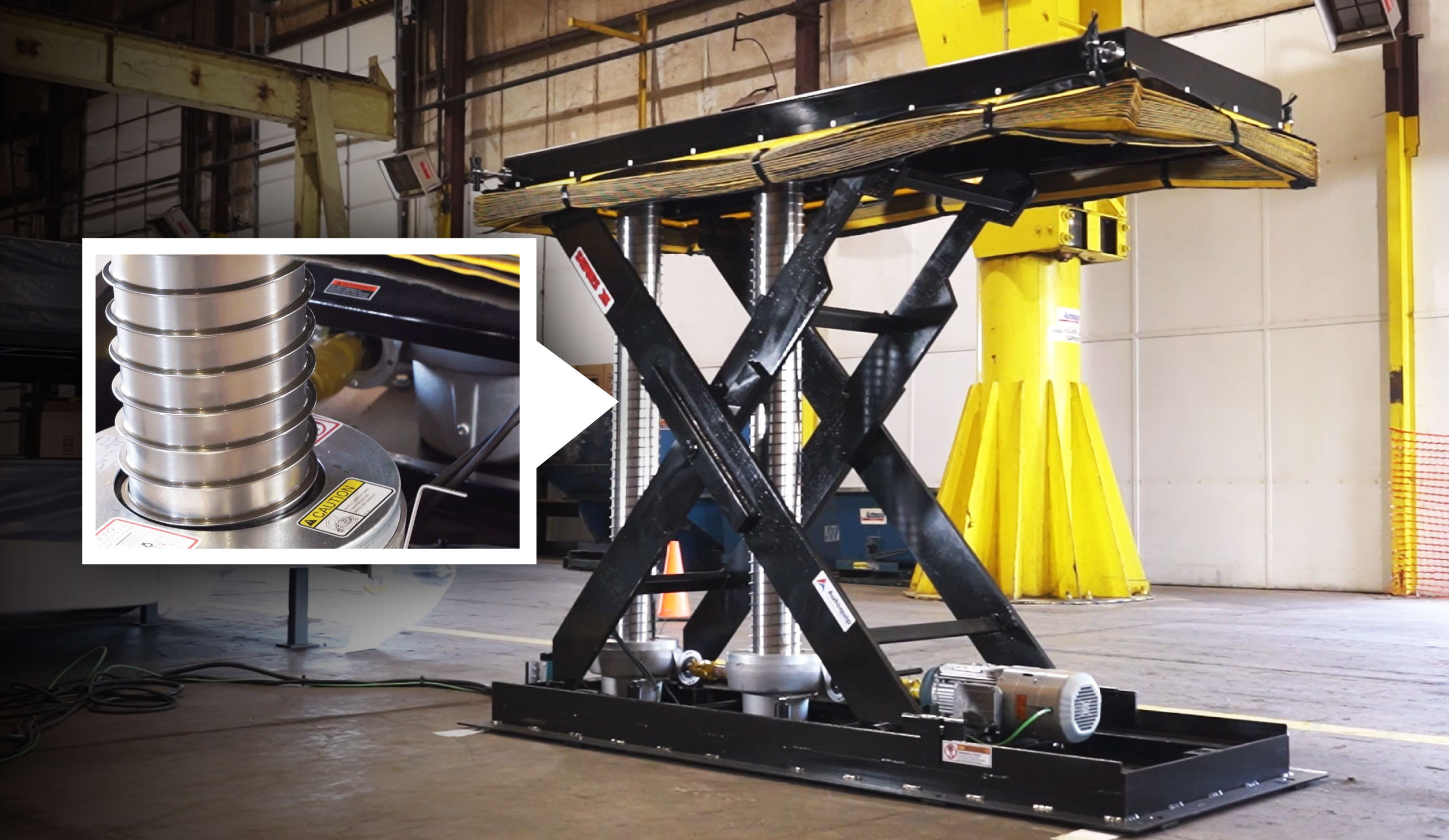

Mechanical Lift Tables

Mechanical lifts offer a high-level of precision and accuracy that are ideal for integrating with automated equipment or conveyor systems where repeatability is key. Driven by electro-mechanical positioning systems such as stacking chains, spiral columns or vertical ball screws, this type of lifting technology provides stable load support throughout the lift’s travel. Programmable mechanical drive (PLCs) allows mechanical lift tables to be called/sent to multiple predetermined levels, which is a critical asset for alignment and precision applications.

In addition to the benefits above, mechanical lift tables are a good option in sensitive environments where there can be no risk of hydraulic fluid leaks. One of the disadvantages is that a mechanical lift has a more expensive cost associated with it than a hydraulic lift. However, the investment will save you money in the long run if you have a highly specialized application.

Pneumatic Lift Tables

Pneumatic Lift Tables are driven by direct-acting, heavy-duty industrial airbag actuators. They provide an economical and dependable solution for transferring, stacking, and shuttling materials and goods over short travels. They are ideal for clean room application where avoiding contamination is important. They also provide a safe lifting solution for operations in explosion-proof or environmentally sensitive locations where there can be no risk of hydraulic leakage, or where there is no standard electrical equipment allowed.

The major downside of pneumatic actuators, however, is that they cannot match the load capacity or travel heights as hydraulic or mechanical lifts. Alternatively, they are the least expensive for a low capacity, minimum travel material handling requirement.

Hydraulic Lift Tables

Perhaps the most popular type of lift table throughout the material handling industry are hydraulic lift tables because of their versatility. Hydraulic actuation works by creating pressurized hydraulic oil in the cylinders that raise and lower the lift. They are suited for many applications such as heavy equipment handling, parts assembly, and ergonomic work positioning. They are available in a wide range of lifting capacities and vertical travel heights. Here are some of the advantages of hydraulic lift tables:

- Versatility: Suited to handle a variety of tasks and applications.

- Safety: Safe and easy to operate.

- Durability: Minimal maintenance is required and will last in the field for many years.

- Economical: A cost-effective solution compared to a mechanical lift.

While there are many advantages to a hydraulic actuated lift, if you are looking for precise positioning, repeatability, and holding, hydraulic lift tables do experience drifting and may not be the best solution in this case.

Other Factors to Consider

Your project’s success is largely dependent on the requirements of your industry, environment, and application. These unique factors can heavily influence the type of actuation you will need. By considering the above information, you’ll be able to make an informed decision about your industrial lift table that will provide you greater equipment longevity, safety, while maximizing your overall investment.

Need help? Autoquip’s technical sales team can provide you expert service and knowledge.