Ensuring Safety with Work Platform Lifts

When manufacturers, warehouses, and distribution centers consider their options for safe and reliable transport of goods and worker access, they look to work platform lifts. The high-performing capabilities of a work platform have been used in the industry for several decades successfully. A perennial choice for over 50 years, they are incredibly versatile, helping companies position oversized equipment, manage heavy loads, and gain access to hard-to-reach projects. And thanks to their design flexibility, Autoquip can customize these lifts in countless configurations to meet the specific needs of your application.

As with any of our lifts, safety is our primary concern. But because work platform lifts are routinely used to move personnel in addition to materials, safety becomes an even higher priority. Let’s review some of the available safety features that ensure your Autoquip work platform lift safeguards your most important asset – your people.

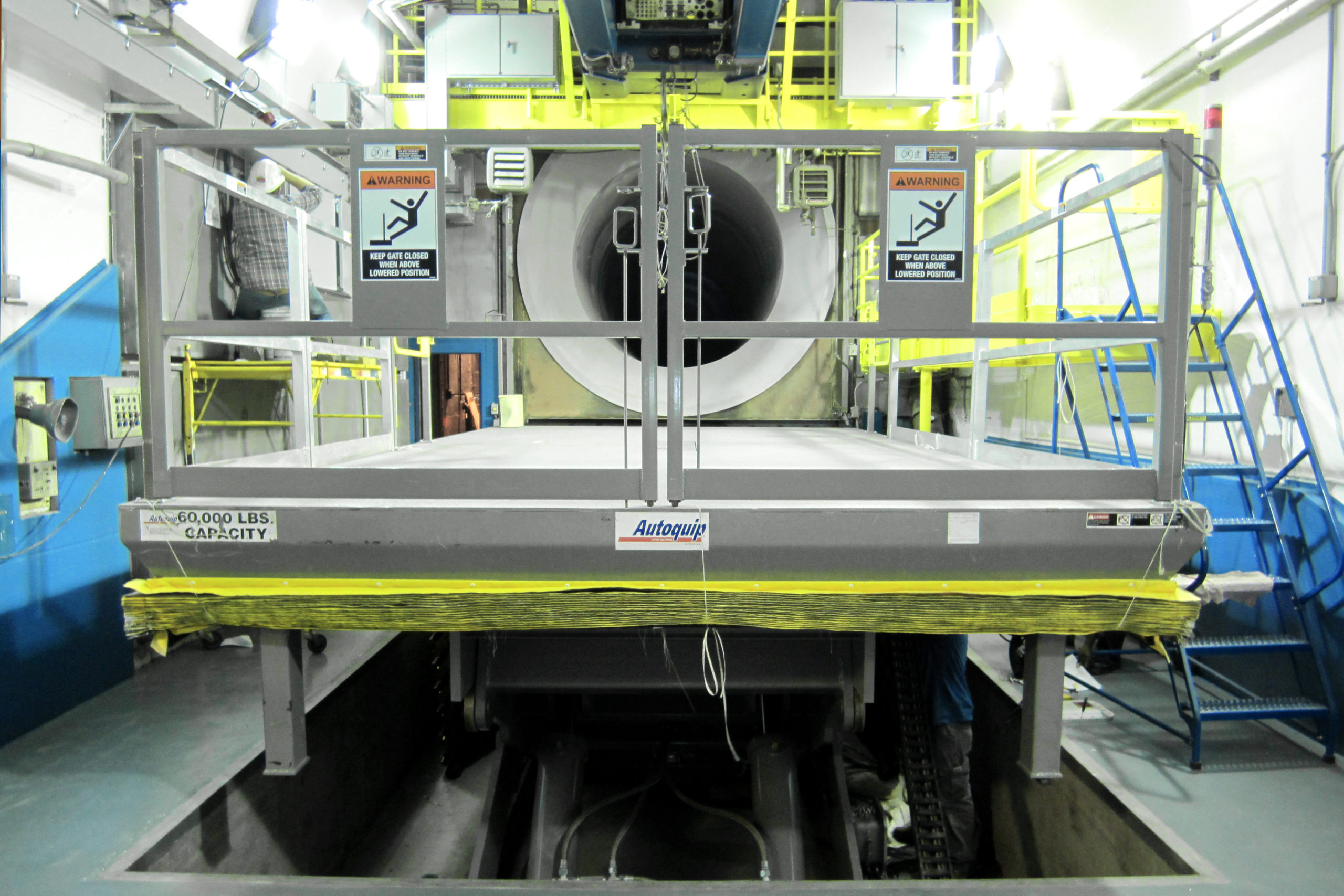

Guardrails

Guardrails work to provide protection from falls by creating an enclosed area atop the platform.

Access Gates

These gates do more than provide an entry and exit point. We design them to work with status switches that prevent the platform from moving unless the gate is completely closed.

Audible & Visual Alarms

Lift-in-motion alarms and flashing lights deliver another measure of safety and awareness by providing visual and audible cues to workers using or near the lift. Audible signals can be tuned to match the area’s noise level to ensure they’re heard.

Intelligent Control Panels

When your application requires a more sophisticated level of safety monitoring, you’ll want to add an intelligent control panel using our cloud-based AQ Connect solution. In addition to performing various programmable tasks, these panels provide access to lift performance metrics, service reminders, and self-diagnostic alerts. Status information is provided on-screen and via remote communications in real-time. AQ Connect creates a safer lift and helps you reduce maintenance costs as well.

Slip Resistant Surfaces

We create safe walking/working surfaces by treating the platform with a slip-resistant finish or by installing a tread plate.

Emergency Valves

In the event of a power failure or other emergency, workers can lower the lift manually with these valves.

Locking Devices

We can install various types of locking devices to ensure that mobile work platform lifts remain stationary when in use.

Protective Skirting

To prevent accidental contact with the sides of a moving platform lift, we can create a barrier using safety skirting. A weighted rod is used to keep the skirting in position.

Harnesses

Some applications require that work be performed over an open or unguarded edge. Our team can design safety harnesses that allow workers to perform their tasks safely and comfortably to reduce the risk of falling or injury.

Are You Ready To Learn More?

Autoquip has been manufacturing custom work platform lifts for decades, so we know that each customer is unique. Our team will work with you to review your requirements, assess your potential risks, and develop a strategy to mitigate them. Using a holistic design approach based on ANSI MH29.1 standards, we can build your custom lift to create a workspace that’s safer and more productive.

There is no limit to the ways Autoquip work platform lifts can be customized and used across industries and applications. Reach out to us for a free quote today, and let’s get started!