Convenient Lift Systems: The Smart Way to Maximize Precision and Warehouse Storage

Today’s industrial applications demand adaptability, safety, and speed like never before. From high-throughput distribution centers to specialized manufacturing plants, the ability to handle materials efficiently and reliably underpins every successful operation. That’s where modern lifting systems come in—especially those custom-engineered by Autoquip, a top leader in the material handling industry for over 75 years.

By integrating convenience, precision positioning, and advanced storage solutions into a holistic approach, we enable businesses to increase production, enhance worker safety, and optimize workflows without compromising on quality. In this blog, we’ll highlight how these key elements can transform your operations and keep you ahead of the curve. For easy navigation, here are the topics we’ll be covering:

- Why Convenience in Lift Systems is a Game-Changer

- Navigating the Intersection of Precision and Efficiency

- Key Benefits of Convenient Lift Systems

- Optimizing the Warehouse Storage Process

- Case Study Highlights: Experiencing Real-World Success with Autoquip Lifts

- Upgrading Your Operations with Our Tailored Lift Solutions

- We’re Shaping the Future of Material Handling

From smarter storage to pinpoint precision, our custom lift systems help you do more. Contact Autoquip today, and let us show you how we can transform your operation.

Beyond Basic Utility—Why Convenience Sets You Apart

In the past, companies viewed lift systems as a necessary but unremarkable component of material handling. However, with the industry’s rapid evolution—and ever-growing pressure to do more with less—convenience has become a game-changing differentiator. Modern lifts are designed not just to move products from point A to point B but to integrate seamlessly with complex workflows, extend existing facility capabilities, and enhance worker productivity.

For businesses of any size, the return on investment (ROI) becomes evident when these systems simultaneously address multiple challenges: easing the load on workers, reducing the risk of injury, overcoming space and shop constraints, and maximizing throughput.

By focusing on convenience as a foundational principle, Autoquip builds solutions that create tangible benefits, whether you’re a new entrant to the world of vertical reciprocating conveyors (VRCs) or a seasoned industrial provider looking to upgrade your legacy equipment.

The Multi-Faceted Value of a Well-Chosen Lift System

Choosing the right lift system can provide several advantages. It doesn’t just move goods; it can revolutionize entire processes. From advanced precision positioning that ensures flawless assembly to versatile VRCs and scissor lifts that handle the heaviest loads, Autoquip solutions offer levels of customization that far exceed anything previously available. By leveraging modern control technology, advanced safety features, and thoughtful design, a well-chosen lift doesn’t simply solve an immediate issue—it positions your organization to remain agile in an ever-competitive marketplace.

Navigating the Intersection of Precision and Efficiency

Industrial operations often demand both speed and painstaking accuracy—a tricky balance to strike. Whether you’re manufacturing aerospace components, assembling intricate parts, or moving large, awkward goods through a busy warehouse, the margin for error can be razor-thin. This is where precision positioning and convenience converge to create powerful outcomes:

- Enhanced Product Quality: We can build lifts that offer accuracies of a tenth of an inch. Operators can consistently place parts where they belong, mitigating costly defects.

- Reduced Downtime: Automated positioning cuts down on operator adjustments, keeping workflows stable and on schedule.

- Safe Working Environments and Stable Operations: Drift prevention systems and sensor-based controls allow for precise alignment, reducing hazards associated with misalignment or unstable loads.

By focusing on both precision and convenience, Autoquip ensures that manufacturing lines, warehouses, distribution centers, and other facilities can maintain optimal throughput without sacrificing quality or safety.

Key Benefits of Convenient Lift Systems

When looking to solve multiple operational challenges, convenience becomes an essential design factor. Autoquip’s solutions address issues that go well beyond vertical transport:

- Safer Work Environments:

- Built-In and Add-On Safety Features: Options like collision detection, audible signals, warning lights, skirting, and custom enclosures protect both workers and products.

- Minimized Manual Labor: By reducing the need for physical lifting or awkward maneuvers, our systems add value by helping lower injury risk and keeping teams focused on higher-value tasks.

- Integration with Existing Equipment:

- Legacy System Compatibility: A new lift doesn’t have to displace older infrastructure. We can retrofit and integrate lifts so that they complement, rather than replace, existing equipment.

- Automation and Controls: From PLCs to advanced control panels like AQ Connect or elite custom solutions available from OSCO Controls, modern lifts can communicate seamlessly with conveyors, robotics, and other machinery for real-time data sharing and performance optimization

- Maximizing Limited Space:

- Vertical Expansion: Facilities nearing capacity don’t always have the option to build out. VRCs and mezzanines allow companies to access additional room by tapping into their overhead real estate.

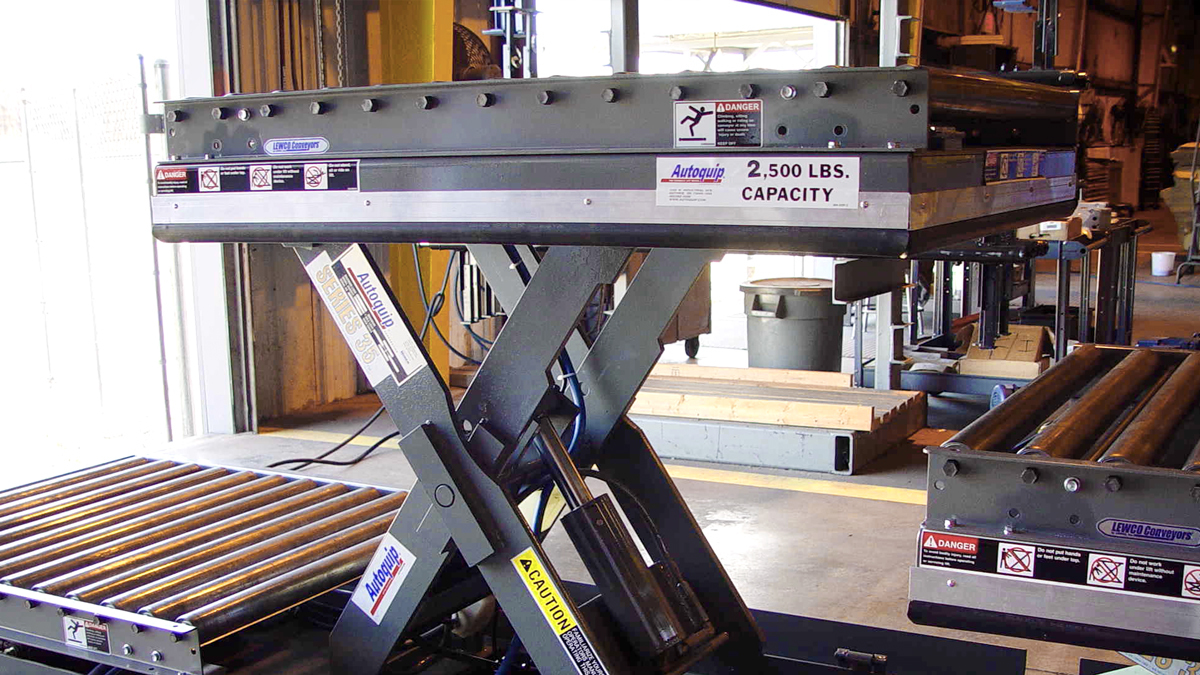

- Higher Load Capacities: For companies looking to expand into heavier or bulkier items, specialized lifts like our Super Titan series of scissor lifts can handle extreme loads without missing a beat.

- Accelerating Load Handling and Workflow:

- Faster Onloading/Offloading: Whether it’s a busy loading dock or rapid-fire assembly line, an optimized lift conveniently speeds the process, reducing bottlenecks.

- Consistent Throughput: By eliminating manual choke points, these systems maintain a steady flow, letting you scale operations more easily.

Optimizing the Warehouse Storage Process

Many companies face the issue of cramped and inefficient warehouse layouts—an obstacle that can make scaling up feel impossible. The good news is that you don’t need to break ground on a new building to expand your usable space dramatically. Vertical solutions, combined with intelligent lift integrations, can provide the tools to help you:

- Go Vertical with Mezzanines: Installing a mezzanine reclaims the area above your existing operations. A VRC or freight lift can safely transport inventory to upper levels without the financial and logistical burden of a major construction project.

- Streamline Flows and Layouts: Optimizing your warehouse isn’t just about adding more racks. It’s also about rethinking how goods move through the space. A carefully placed lift system can shorten travel distances, reduce forklift traffic, and improve overall efficiency.

- Future-Proof Your Operation: As demand ebbs and flows, a well-designed vertical storage system plus a robust lift can adapt to changing volumes and product categories—no massive renovations required.

Case Study Highlights: Experiencing Real-World Success with Autoquip Lifts

The synergy between convenience, precision, and efficient storage isn’t just theory; it’s part of Autoquip’s proven track record. Below are five case studies showcasing the impact of our tailored solutions across diverse applications:

- Mechanical VRC Transports Donated Goods to Three Levels

- Challenge: A non-profit needed a reliable way to move donated items to multiple building levels without straining volunteers or risking product damage.

- Solution: We designed a multi-level mechanical straddle vertical reciprocating conveyor (VRC) for stable, efficient transport. Safety features and robust load capacity ensured smooth operation.

- Outcome: The facility expanded its storage and sorting capacity, enabling quicker turnaround for donation processing and increased service to the community.

- Automated VRCs for AGV Rack System Retrieval and Storage

- Challenge: A manufacturer of automated liquid handling systems needed a faster, more efficient way to move AGVs and pallets between rack levels to streamline storage and retrieval.

- Solution: Autoquip designed a 4-post mechanical VRC with drag chain conveyors and stability enhancements, fully integrated with the AGV system via a smart control network.

- Outcome: The automated VRC improved throughput and operational flow, enabling seamless multi-level transfers and maximizing storage efficiency.

- Integrated Pipe Handling and Rack Lift System

- Challenge: Large and unwieldy piping required precise positioning within a busy manufacturing environment to ensure worker safety and product integrity.

- Solution: A specialized multi-lift system was integrated with the customer’s existing equipment to create a cohesive manufacturing process.

- Outcome: The project resulted in improved production speeds, reduced labor costs, and safer handling of oversized materials—leading to a significant boost in overall efficiency.

- Advanced Ergonomic Work Platform System for Aerospace Industry

- Challenge: Aerospace technicians needed a stable, adjustable platform for intricate assembly tasks. Even a slight misalignment could lead to defects or pose safety hazards.

- Solution: We created an ergonomic work platform that offers multiple horizontal positions and vertical heights, ensuring consistent accuracy and reduced physical strain on workers.

- Outcome: The implementation resulted in shorter assembly times, higher-quality output, and a safer environment that allowed technicians to maintain the precision demanded by the aerospace sector.

- Heavy-Duty Powered Scissor Lift Integrates with Automated Robotic Stacking Line

- Challenge: A facility running 24/7 needed a robust lift to keep pace with an automated robotic system stacking heavy products for shipping.

- Solution: A high-capacity scissor lift designed to synchronize with the robotic system’s timing and movement.

- Outcome: Smooth, uninterrupted production flow with minimized downtime and substantially higher throughput, allowing the company to meet increasing customer orders effortlessly.

From non-profits to aerospace, these stories underscore the broad applicability of convenient, well-integrated lift systems and how they can revolutionize day-to-day operations.

Upgrade Your Operations with Our Tailored Lift Solutions

At Autoquip, we believe that every operational challenge is an opportunity to excel. Whether you’re looking to streamline workflows, enhance safety, or optimize space, our tailored lift solutions are built to deliver lasting impact.

Are you ready to address multiple challenges—like space constraints, safety concerns, and labor efficiency—in one intelligent move? Contact us for a free quote today and learn how our custom-designed lifts will not only meet your specific requirements but elevate your entire operation.

Autoquip: We’re Shaping the Future of Material Handling

In an era of relentless competition and ever-rising customer expectations, finding ways to sharpen your operations isn’t just a matter of staying afloat—it’s about flourishing. By embracing convenient lift systems, companies can reduce manual labor, optimize storage, and elevate their workforce to focus on higher-value tasks.

Whether you’re integrating new technology with legacy equipment or starting a major warehouse redesign, the right lift strategy can be a catalyst for transformative growth. Through decades of expertise, Autoquip has proven that success is about more than manufacturing great lifts; it’s about engineering comprehensive solutions that address your unique pain points and ambitions. By merging precision positioning, cutting-edge safety features, and advanced storage techniques, we create systems that stand the test of time—even as your business evolves.

If you’re looking to future-proof your operation, streamline workflows, and build a safer, more efficient working environment, reach out to Autoquip today. Discover how our “Lifts Without Limits” philosophy can empower your team, enhance your facility, and drive real competitive advantage in the world of modern material handling.