Automatic Indexing Lifts for Sheet Feed

Introduction

Standard hydraulic lift is easily programmed to automatically adjust to the height of conveyor feed.

Project Challenge

A woodworking customer approached Autoquip with the challenge of creating an affordable, adaptable, and precise indexing lift that would automatically adjust its height as sheets of wood were either added to, or removed from, the top of the lift. Most conventional programming that is required to accomplish automatic indexing is cost-prohibitive and difficult to modify by the average maintenance worker once installed.

The challenge given to Autoquip was to develop a means of converting hydraulic scissor lifts already in the field to:

- automatically index either up or down (depending on the application) regardless of the material thickness being processed.

- be accurate to within 0.10″.

- be affordable.

Our Solution

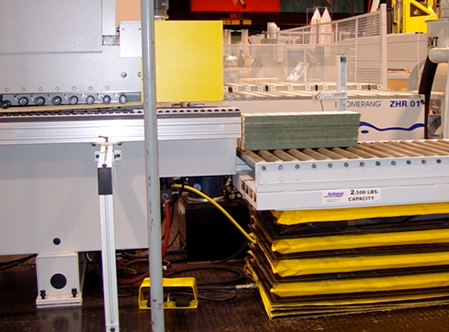

The controls engineers at Autoquip accepted the challenge and developed a “universal” indexing technology that could be used in any type of sheet feed operation (material thicknesses 1/8″ and up), whether stacking or de-stacking, to automatically adjust the top of the material stack to a pre-determined elevation. That elevation could simply be an optimum ergonomic height, or it could be the elevation of the infeed or outfeed of a planer, saw, press, etc. Best of all, this technology can be easily applied to either new or existing hydraulic scissor tables.

The indexing technology involves the use of photoelectric sensors that can be set to sense either light or dark, and to place these sensors in a circuit so that signals can be sent to either the hydraulic motor (for UP movement) or the hydraulic dump valve (for DOWN movement). The lift will initiate movement without any human interface, and automatically stop movement when the photo-eye sees light or dark once again. Simple, adaptable, and separate from what is otherwise a basic hydraulic lift and power unit. The customer has been very satisfied with this affordable retrofit feature, and has since had this feature added to new equipment purchases as well.

Lift Specifications for this indexing application:

Lifting Capacity: 2,000 lbs.

Platform Size: 30″ x 70″ with gravity rollers

Vertical Travel: 48″

Control signal: Photo-eye sensor

Actuation: Hydraulic

The Results

Automatic indexing is made simple, adaptable, and affordable by utilizing an off-the-shelf photo-eye sensor to incrementally raise (or lower) an otherwise standard hydraulic lift.