Ergonomic Fixtures Improve Productivity

Introduction

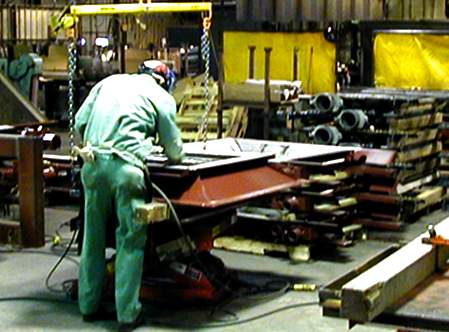

Gate manufacturer installs an ergonomic workstation lift and turntable beneath existing welding fixtures.

Project Challenge

Powerbrace Corporation was challenged to improve the quality and throughput of gates being welded at their various welding stations. Welding fixtures were mounted to fixed-height welding tables, and efficiency was suffering in part due to poor ergonomics at workstations. Welders were forced to bend and reach excessively to access their welds. Powerbrace came to Autoquip requesting a material handling solution that would improve workstation ergonomics, and subsequently improve quality and throughput.

Our Solution

Manual welding stations are benefited from a solution that provides the operator incremental adjustments in both elevation and rotation of the work. A hydraulic lift was recommended as the most cost-efficient method of providing adjustments in elevation, in order to keep the welded product at an optimum, ergonomic work height. The ability to rotate the welding fixture is also critical in order to minimize walking around the product to access welding. In addition, Autoquip also recommended that the lift be operated via a floor-mounted foot pedal rather than a hand-held pushbutton station. This way, the lift can be operated by the welder in a “hands-free” way – avoiding the inefficiency associated with setting down and picking up his welding rod, welding hood, etc. in order to adjust the lift’s height.

The customer is completely satisfied with this work station improvement, and worker productivity and quality have improved as a result of keeping the work more nearly within the ergonomic “power zone” of the welders. Lift

Specifications for this Unique Application:

Turntable Model: SR4-48-25

Lift/Turn Capacity: 2,500 lbs.

Vertical Travel: 24″

Platform: 48″ x 48″

Actuation: Hydraulic (Lift)

The Results

Through the addition of a hydraulic lift with manual turntable, each welding station has been cost-efficiently updated to include a vital worker productivity improvement, thereby increasing product quality and factory throughput.