Personnel Work Platform for Mixing Vat Processing

Introduction

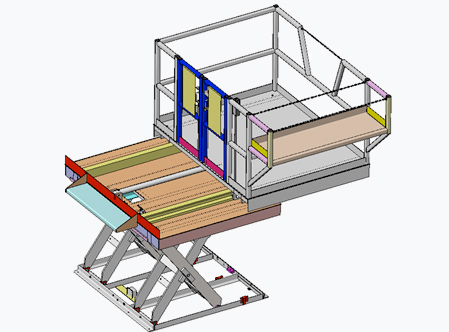

Personnel work platform with adjustable shuttle deck extends both vertically and laterally.

Project Challenge

Intermetro Industries needed a way to “position the worker closer to the work of a mixing vat – in an effort to improve the process of transferring material to the vat for mixing purposes. Customer has been using rolling ladders for workers to carry the paint up and down steps to the mixing vat. Customer’s primary challenge was to be able to install a permanent work platform without impeding traffic in the 48-inch wide aisle adjacent to the vat.

Our Solution

The Autoquip design team ultimately recommended and designed a doublewide scissor table lift system for this application. The double-wide design was required because of its increased edge load capacity – which was necessary to accommodate the weight of the telescoping shuttle deck as it was extended up to 54 inches over the edge of the lift platform to temporarily span the aisle adjacent to the mixing vat. The powered shuttle deck was actuated by a double acting hydraulic cylinder mounted between the scissor lift deck and shuttle deck.

Operator controls for UP/DOWN/IN/OUT motions were mounted in a push button station, which was mounted to the guardrail on the perimeter of the work platform. This total hydraulic solution was exactly what the customer needed to provide employees of varying height and reach both safe and ergonomic access to the mixing vat.

Specifications for Equipment Specs:

Lifting Capacity: 1000 lbs.

Platform Size: 72″ x 90″ with non-skid walking surface & OSHA-compliant guard rails

Vertical Travel: 48″

Horizontal/Shuttle Travel: 54″

Lifting Speed: 15 sec

The Results

Through the use of this customized scissor lift, the mixing process has been cost-efficiently updated to include a vital worker productivity improvement with minimal impact on the surrounding aisle space.