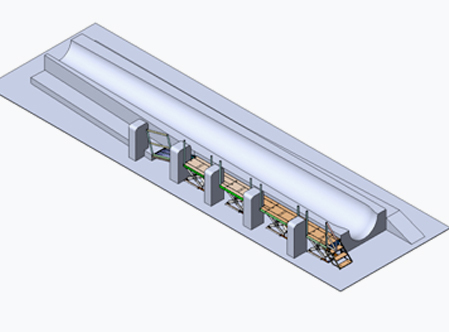

Wind Generator Blade Work Platform

Introduction

28-foot-long adjustable work platform provides variable work heights for assembly workers of wind generators.

Project Challenge

Vestas Wind Systems needed a method to lift workers and their tools to various work heights for access to their mold system. Their former process of using multiple ladders was extremely inefficient and potentially unsafe.

A powered work platform solution had to meet the following constraints:

1) nested within existing mold support columns and limited floor space available.

2) be as low profile as possible when collapsed.

3) provide an even, level, elevated working surface just over 28-feet long.

4) must have an on-board access ramp (for tool boxes) and stairs (for workers) that would travel up and down with the work platform.

Our Solution

After a review of the detailed floor plan in the assembly area, and after discussions with the end-users of the equipment, Autoquip recommended a custom-designed multiple-scissors lift system that could share a common, one-piece walking surface over 28-feet long. This system consisted of four (4) individual scissors lifts, each with its own dedicated hydraulic power unit, spaced evenly to support the working platform from beneath. Hinged walking decks were attached between the individual scissors lift platforms and were notched to clear the various support towers/columns that were adjacent to the mold system. Lift synchronization was achieved via a central control panel which, when a single button was pushed, would start/stop all individual hydraulic power units together and provide a walking surface over the entire 28-foot platform that would be level within 1 to 2 inches. A hinged, on-board staircase was attached to one end of the work platform, and a hinged, on-board access ramp was attached to the opposite end of this custom lift. Product details for this customized powered work platform system:

• Lift Family: Series 35

• System Capacity: 2500 lbs.

• Overall Platform: 32″ x 339″

• Vertical Travel: 24″

• Actuation: Hydraulic

The Results

Customer has benefited by this customized scissor lift work platform through:

1. Improved worker safety and ergonomics with variable height adjustment of the workers and their tools.

2. Increased efficiency/throughput by eliminating the use of ladders and reducing the number of manual tasks required to do their job.

3. Zero building modifications required.

4. Receiving both the equipment and installation from a single source (Autoquip).