Improving Processes with Community Tool Boards

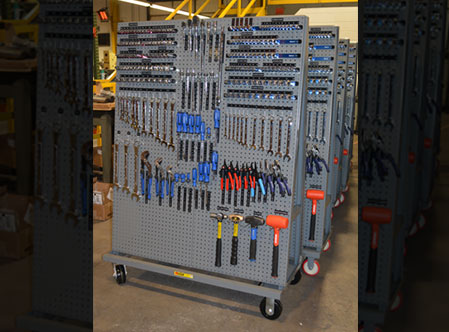

Autoquip is committed to lean manufacturing process improvements. We are taking steps to improve our efficiency and lean implementations. One of Autoquip’s recent steps is to provide our employees with tools and tooling that will help them improve their efficiency and reduce physical demand. This in turn will allow our workers to maintain a high level of production for a longer period of time. To achieve this, Autoquip is installing community and work cell tool boards for each manufacturing department and work cell. Each work cell will have the tools that are needed on a daily basis located conveniently for their use. In addition to the work cell tool boards, Autoquip is providing community tool boards for each department for the tools used less often. By providing the tools in these two methods, the employee is not overcrowded with tools they do not need daily and the tools they need less often are still readily available. Autoquip has recognized a need for improving the employees work environment and by providing the tools they need will help reduce the burden of the employee having to purchase their own tools. In most cases, this also translates to an improvement in the quality of the finished product as typically higher quality tools are provided which in turn reduces rework.

Autoquip has begun expanding this method to other areas of manufacturing by our “No Doors or Drawers” policy. Gradually we are replacing our older storage locations that have doors and drawers with newer storage locations that provide an open-faced method. Using the open-faced shelves and cabinets removes the clutter collector temptation of putting items where they are out of sight and out of mind. This method keeps everything in view so it can remain organized, clean and available to the employee. In addition, the open-faced method aids in inventory management as the supervisors can visually determine if a product is getting low for re-order.

To top off the aforementioned improvements, Autoquip is moving forward with a robust 5S program to improve the quality of work, reduce lead times and improve manufacturing processes. It is Autoquip’s mission to provide our customers with a product that is superior in quality to our competitors and in an efficient manner that will exceed their expectations.