Aerospace Lifting Solutions & Challenges

The industrial equipment used to assist the manufacturing processes in aerospace production requires the greatest degree of precision and intricacy, Autoquip delivers custom lifting solutions and new controls technology capable of meeting all the accuracy and precision critical to producing high-quality aircraft and parts.

We Solve Industry Challenges

Seven decades of elite experience has uniquely positioned Autoquip to tackle the various challenges in the Aerospace field. Discover our library of case studies, design options, and successful lifting solutions that have achieved successful outcomes for our customers.

1. Spacecraft Manufacturing & Testing

Our Air-Powered Transport Lift is an application designed specifically to work with an engine crawler table capable of positioning a rocket engine to a test stand. The unit lifts the rocket engine from ground level and places it onto the crawler table. Leveraging a scissor lift mechanism and the mobile base provides the operator with the ultimate positioning flexibility.

2. Test Cells & Specialized Maintenance

With a capacity of 6,000 pounds and a platform measuring 324” by “504”, The Quad Platform Lift is one of Autoquip’s largest. It features four hydraulically-actuated pit mounted Tork 1 scissor lifts under the platform with cable transducers (1 per leg set) to provide the controller’s travel feedback. This durable lift is ideal for customers managing test cells or performing specialized maintenance.

3. Aerospace Tooling Solutions

Autoquip solves complex tooling requirements by designing custom tilters to streamline operations. We created a custom 90-degree Upender Tilter per our customers’ exact specifications. The unit features a double-load locking device and taller platform sides. The design delivers an ergonomic solution that improves efficiency, safety, and technician satisfaction.

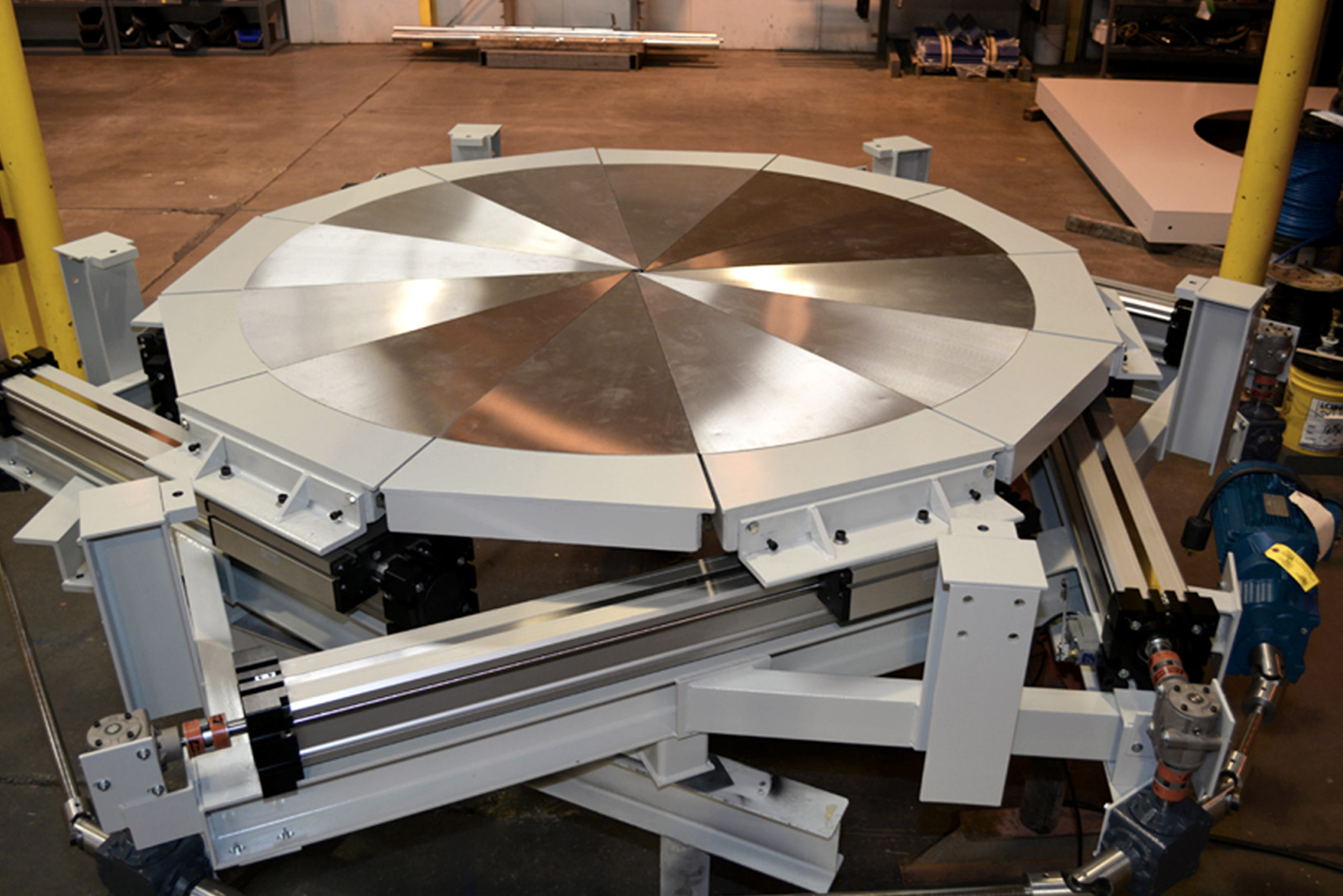

4. Automated Scaffolding for Jet Assembly

When a customer requested a 360-degree scaffold lift system to improve their jet engine inlet operation, Autoquip delivered. The unit consists of multiple platform lifts. One at the center is positioned inside the inlet tooling. Two sets of quad lift platforms are used to construct the outer scaffolding. This design provides workers with the ability to complete the inlet assembly process safely.

5. Lift Equipment Status Monitoring

Create and maintain a streamlined and safe working environment by installing a custom monitoring solution. The AQ Connect Smart Controls System intelligently monitors your equipment, performs diagnostics, and provides essential system feedback to keep your operations running smoothly.

Your Innovation Partner

As the leader in innovative lifting equipment, Autoquip is committed to problem-solving. We work closely with our customers, so we are keenly aware of the challenges they face. Our commitment to collaboration allows us to develop unique custom solutions that deliver exceptional results.

Are you looking to improve worker safety, streamline production, and increase revenue? Let us put our technical and engineering expertise in aerospace lifting options to work for you

Ready to Learn More?

We understand that you have specific and complex project requirements. We have the tools, resources, and skills to create a design that exceeds your expectations! Request a free quote today, so we can start building a solution for your operation!