Applications

Conveyors

Autoquip has been providing standard and specialized equipment solutions for conveyor applications for over 70 years. We have designed custom conveyor solutions with applications involving lifting, turning, and tilting. Autoquip can apply extensive design experience and our comprehensive design database to develop an effective, reliable, and custom lift solution that will meet the demands of your particular conveyor application.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for conveying applications include:

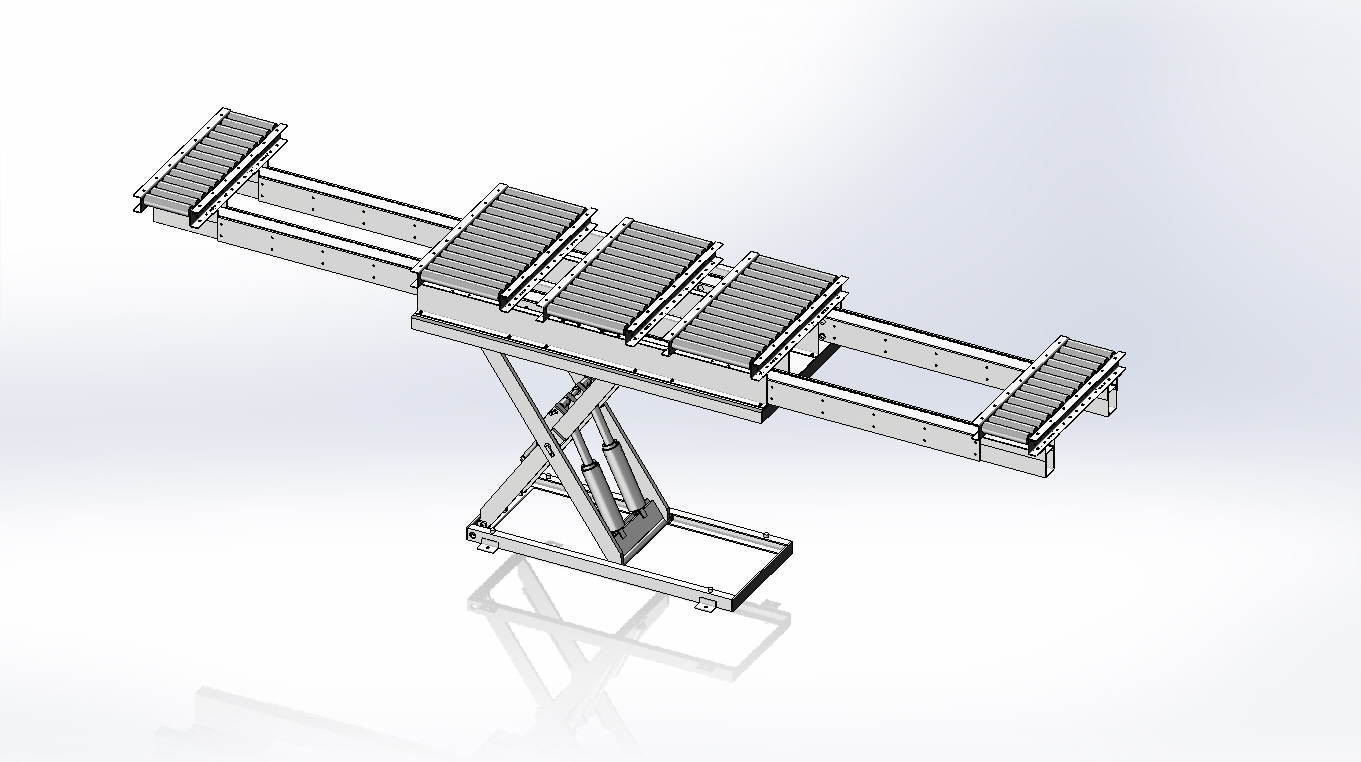

Scissor lifts with turntables, gravity conveyors, or powered conveyors are used in the production of batteries, engines, transmissions, panels, etc.

Hydraulic scissor lifts are equipped with enhanced mechanical and structural features to extend the serviceable life of the scissor lift in extreme, high speed, and/or high cycle production applications. It can also be used with and without a conveyor.

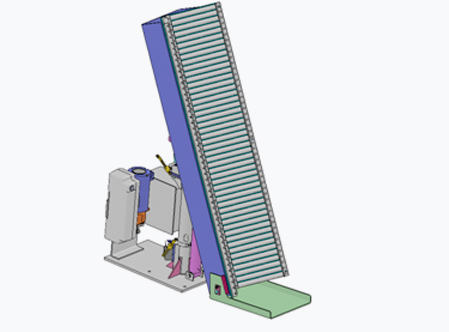

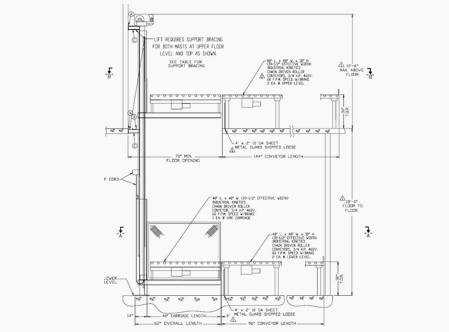

A mechanical vertical reciprocating conveyor lift with a powered conveyor bed automatically controlled in a multi-level conveyor system processes pallets of paper.

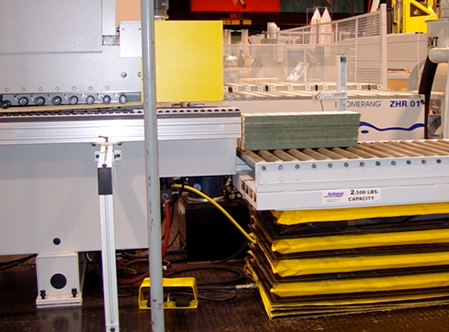

A high-capacity, single-acting scissor lift with a powered conveyor is used in side-transferring empty "skillets" in an automotive assembly process.

A heavy-duty scissor lift with a powered conveyor mounted to a powered transport base receives and transfers stacks of sheet metal to a blanking operation.

Industrial scissor tables with manual or powered turntables builds up layers of finished product onto pallets for shrink-wrapping.