Applications

Precision Positioning

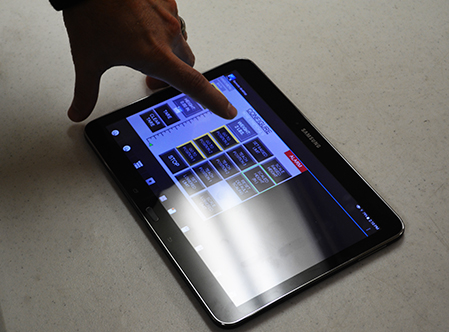

Autoquip boasts an unmatched ability to provide solutions for precise positioning applications at competitive prices. Our hydraulic lifts equipped with electrical transducers and controlled by programmable controllers (PLC) can achieve repeatable accuracies as precise as one tenth of an inch.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for applications requiring precise positioning include:

A system of eight hydraulic lifts, each equipped with a vertical transducer and controlled by a central motor control panel with PLC, keeps an entire 50-foot-long modular home level within ¼" during raising and lowering.

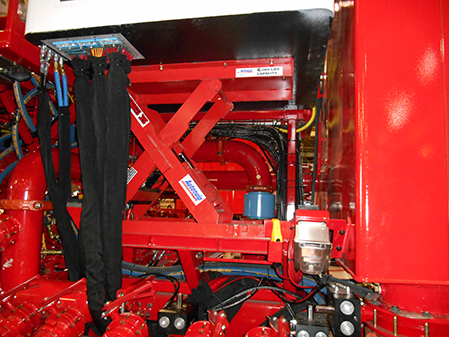

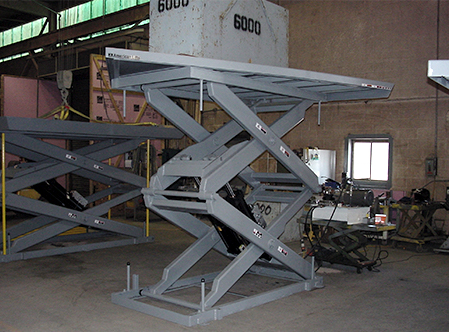

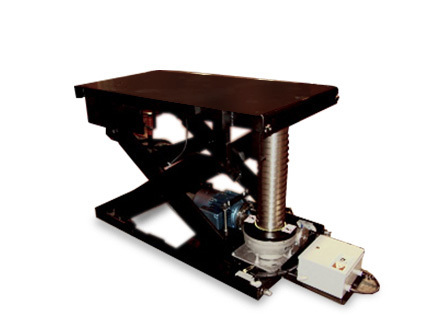

Scissor tables with a mechanical spiral mechanism and PLC controller can raise the lift deck to precise, pre-determined heights.

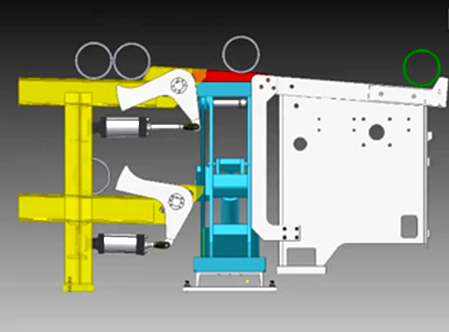

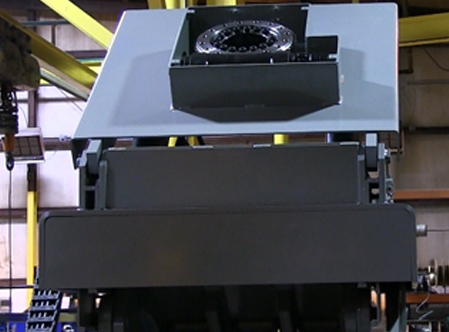

A mechanical turntable with an encoder must rotate in accurate 90-degree increments for the robotic welder to be positioned correctly for spot welding.

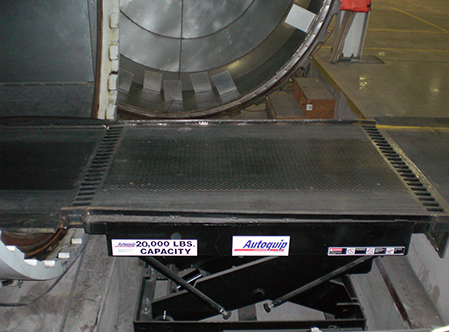

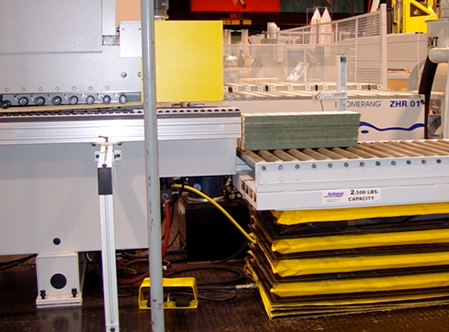

A high-capacity hydraulic lift, equipped with linear transducer, is pre-programmed with the PLC to stop at precise elevations during sheet transfer from the lift to an adjoining conveyor.

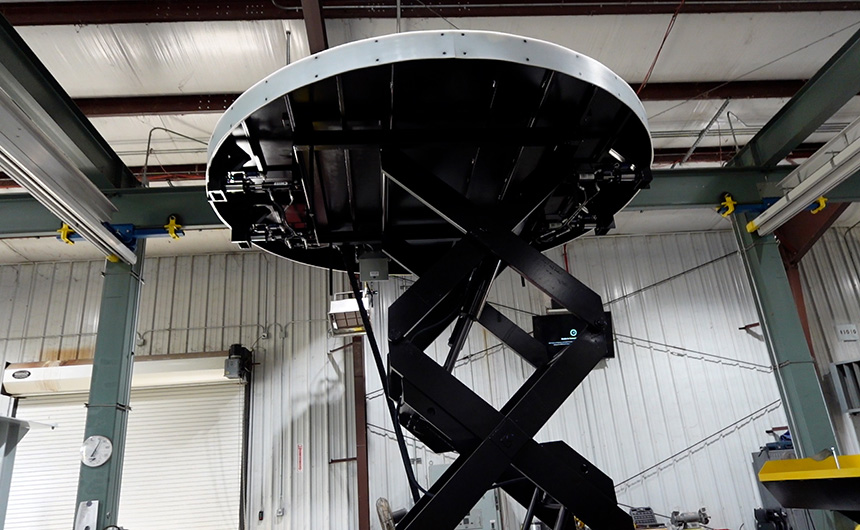

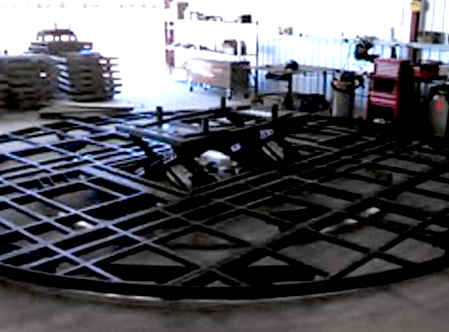

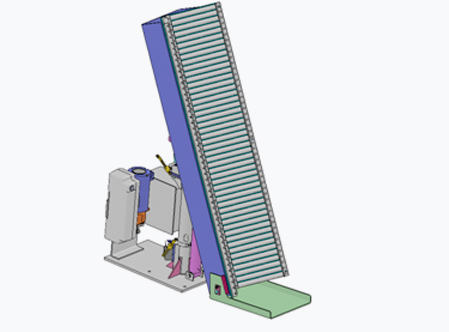

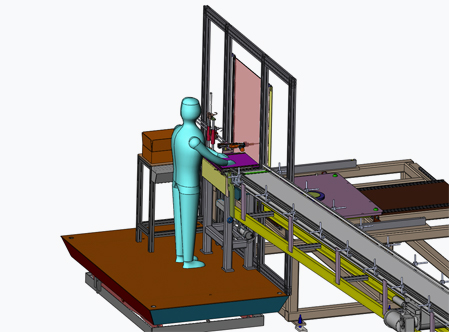

Large, ring-bearing turntables with a rotary encoder and PLC controls precisely positions sheets of metal for scoring and marking just upstream of the blanking machine.

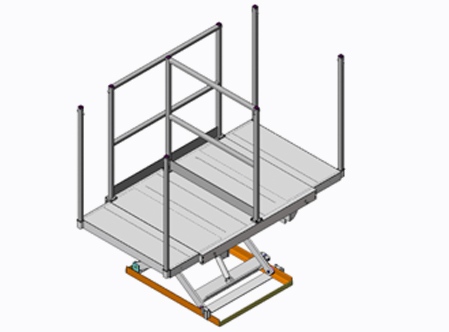

Mechanical scissor lifts, driven by a mast-mounted gear drive system and programmed for use in a conveyor over/under system, can raise and lower product from one elevation to the other.